Summary

Maintenance Engineer to Powerhouse Manager, 1984-2005.

Doug Howden, Kodak Australasia Pty Ltd: Maintenance Engineer, Powerhouse Manager, 1984 -2005

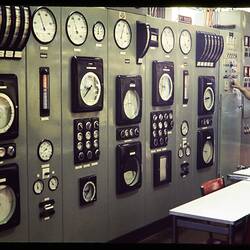

Doug Howden did his apprenticeship as an instrument technician with Australian Paper Mills and gained experience working with a number of other firms over several years. Doug was responsible for the instruments that controlled machinery, particularly boilers. Doug explains:

"You have to control the machinery and you have to control it automatically without too much intervention from people. So you want to control your boiler pressure, you have a pressure sensor, a pressure transmitter, it goes to a pressure controller and it compares the pressure that you have with the desired pressure, then it'll actually send a signal off to your fuel valves, air valves and so forth."

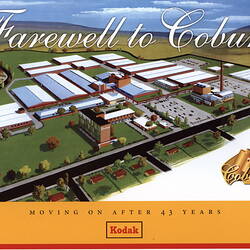

Doug was familiar with Kodak Australasia's Coburg plant, having worked there as a contractor during the annual shutdown, when extra technicians were brought in to augment Kodak's regular maintenance team. Doug was impressed with Kodak's factory, which was well maintained compared with some other factories he had seen. This influenced Doug in his decision to apply for a job at Kodak in 1984.

Kodak's Coburg Maintenance Workshops

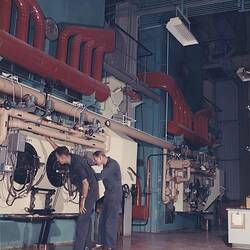

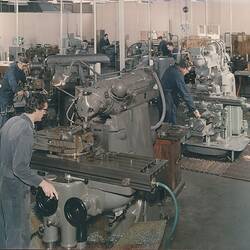

Doug commenced work as part of the maintenance team in the instrument workshop. This was one of several trade workshops in Building 12, the maintenance and construction centre for Kodak's Coburg plant. Having a background in steam, Doug's particular area of responsibility was the powerhouse. He was soon promoted to a leading hand, becoming the instrument foreman a few years later.

Kodak's technical staff took a pride in way they maintained the plant and machinery in good working order. Doug remembers that this involved teamwork between the trades, particularly during the annual factory shutdown when the machinery was overhauled and new plant installed:

"You all had your own part to play. And there was a bit of a competition about who was in front. Were we in front of the plumbers, were the plumbers in front of us? The electricians were waiting for everybody. It was good natured. We had a plumbing foreman there called Peter Oakley who had been a Collingwood footballer in the early league. He created a bit of this atmosphere and he'd say, 'How are you going?' I was the instrument foreman and he was the plumbing foreman, so he's putting the pipework in, I put the valves in."

Doug was part of the team that upgraded the coating track used to make colour film in the 1990s. Making colour film involved coating a base material with layers of light sensitive silver halide emulsion, using a draw-down system to bring the emulsions to the track via hoppers. Doug worked on the control panels, switches and meters that controlled the rate of flow and the temperature of the emulsions. It was vital that the emulsions were heated and cooled at the correct temperature gradient, determined by Kodak's chemical engineers, to ensure that the product met quality standards. This control required the skill of the instrument technician, which was more than 'simply switching things on and off'.

Kodak's tradition of maintaining and building its own plant was to change from the late 1980s, when the central workshops were closed and contractors brought in to do large maintenance and installation works. Doug moved to the coating track as a shift engineer, a job that involved understanding the equipment and the interface between its components. If there was a breakdown he knew which tradesman to call, or in some cases, find the solution himself.

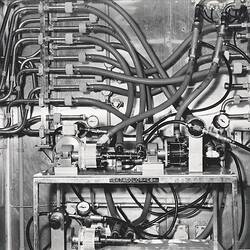

The Powerhouse

As shift engineer Doug was still assigned to the powerhouse, ready to fix any problems that cropped up there. On one occasion he was called on to solve a major problem at the powerhouse, and remained for ten years, becoming powerhouse manager in 2003. The powerhouse (Building 11) was one of the first buildings constructed on the Coburg site, and was central to the factory's workings. It generated steam used for process heating, power for the factory, refrigeration for air conditioning, compressed air and various grades of water used in Kodak operations. Doug had a particular fondness for the powerhouse:

"It was state of the art, it was good quality. One of the advantages about working with high pressure plant is that it's always good stuff. You can't afford for it not to be. Generally people don't want to go near the powerhouse because it's a big aggressive thing, it makes a lot of noise. But because everything is high pressure, it's really well made, really well designed and generally a pleasure to work on, and doesn't break down all the time. It is the heart of the place. I think when people are talking about an office system, they'll use industrial terms, and say, 'This is the engine room of the business'. That is the engine room. I was brought up with it from the time I was sixteen, so it was second nature to me."

Kodak's downsizing resulted in the integration of operations and maintenance in the powerhouse. Consequently the engine drivers were trained in trades and the tradesmen, including Doug, did their engine drivers certificate. After the Kodak factory closed in 2004, Doug stayed on to run the powerhouse and provide steam for the remaining operations as the complex was dismantled. One of the last buildings to be demolished was the powerhouse:

"We were watching the stuff that we looked after for years being dismantled and sent to scrap. That was a bit strange. And when we shut down and cut the things up those boilers were perfect. So after all of those years, they were well looked after."

After Kodak

After his employment at Kodak finished in 2005, Doug worked as an engine driver in a refrigeration plant. He thought the working conditions were 'third world country sort of stuff', compared with Kodak: 'We used to call it 'Mother Kodak', and you were looked after.'

References

Whinney, Daryl, R. (ed) 'A Brief Process Based Site History: Kodak Australasia Pty Ltd, Coburg Plant', 2007 (Museum of Victoria Library).

HT 36535 - Interview with Doug Howden, interviewed by Lesley Alves at Melbourne Museum, 12 February 2014.

More Information

-

Keywords

Factories, Engineers, Biographies, Maintenance, Electrical Engineering

-

Localities

-

Authors

-

Article types