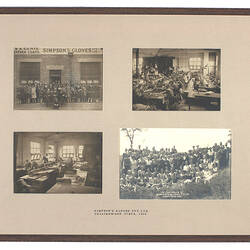

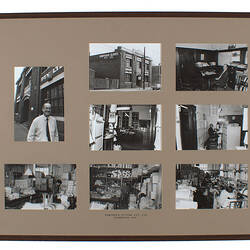

Production processes in the making of coats, gloves and handbags did not change greatly in the period from the 1920s to the 1980s, apart from the introduction of hydraulic leather cutters and new sewing machines.

Designs for the gloves and coats were usually drawn by Amos Simpson. Handbags were designed by the foreman Ernest Stokes Munro, and then subsequently by his son Keith Munro. The bulk of the leather came from Victorian and South Australian tanneries. Every part of the leather was used, with the smallest pieces being used for trim on hats or purses.

The pattern was placed on the leather on the cutting table, and cut by hand; subsequently the leather was placed under the pattern press that stamped the piece out. For handbags, leather and linings were pasted together by assemblers, then sent on to the machinists. For coats and jackets, the patterns were used to cut the linings and leather, and then sent to the machinists. One cutter could keep several machinists busy.

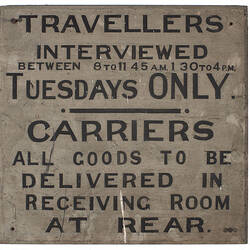

The factory was divided into several departments: cutting; table assembly; handbag department; coat machining; and glove machining. Men were used exclusively to do the designing and cutting; women did the assembly and machining. The cutters and assemblers stood at their work benches to do their work; machinists sat at their machines.

Archives:

The University of Melbourne Archives holds business records relating to the company, including ledgers, journals, wages books, time books and catalogues.

References:

Frances, Raelene (1986).'No More Amazons: Gender and Work in the Victorian Clothing Trades, 1880-1939', Labour History, no 50: 95-112.

Interviews with former managers and workers: Arthur Atkins (1989), Ernie Jordan (1989), Nell Marks (1989), Hazel Eddy & Gwen Simons (1990).

More Information

-

Keywords

-

Authors

-

Article types