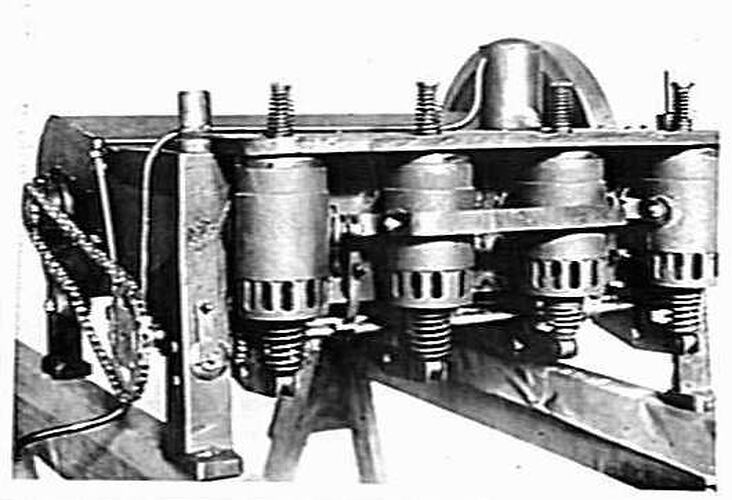

The engine used on Orville and Wilbur Wright's 1903 Wright Flyer was designed and built mostly in the workshop behind their bicycle shop in Dayton, Ohio. Following the success of their earlier glider trials in 1900-1902, Orville began work on the design of an engine in December 1902, while Wilbur concentrated on designing and constructing a suitable propellor. Orville was assisted in building the engine by the mechanic Charles Taylor, who the Wright Brothers had originally hired in 1901 to help manage the mechanical work associated with the bike shop, while they foused on their flying experiements. Working from just rough sketches and with no detailed engineering drawings, Taylor had the parts machined and assembled ready for a first trial run on 12 February 1903. The engine was of an advanced four-cylinder in-line horizontal design, with 4-inch bore x 4-inch stroke (102 mm x 102 mm), weighing just 140 pounds (63.5 kg) - including a 30 pound (13.6 kg) flywheel, and proved capable on a brake test of delivering 8.25 horsepower (6.15 kW) at 670 revolutions per minute and a little over 11 horsepower (8.2 kW) at 1,000 r.p.m. Amongst the more innovative features of the engine was the lightweight crankcase and cylinder block machined from a single casting in a special alloy of aluminium and 6 percent copper, into which were fitted thin cast-iron cylinder liners.

Initial technical problems caused the crankcase to fracture when the bearings froze after less than a day of testing and it took until 20 April for a replacement castign to be obtained from the foundry, but Orville and Charles Taylor had the rebuilt engine successfully running by May 1903. The engine was coupled to two 8.5 feet (2590 mm) diameter propellors using chain drives, similar to an oversize bicycle chain - a feature that would later be used by Duigan and other aviation pioneers. Confident that their engine would develop the required power-to-wieght ratio, the Wright Brothers set out for Kitty Hawk for a further round of flight trials on 23 September and achieved their first manned powered-flight on 17 December 1903.

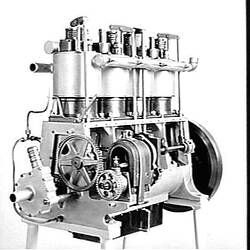

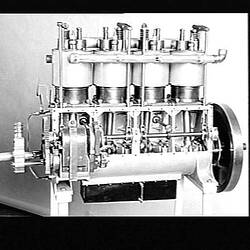

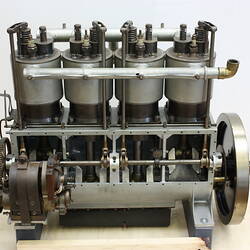

By 1906 Orville and Wilbur were improving their engine with each brother developing a different design. Orville's new engine was a vertical four-cylinder water-cooled unit capable of producing 40 horsepower (30 kW) at 1,500 revolutions per minute. Unlike the 1903 engine, the cylinders of this new design were separate iron castings which were bolted to the cast alumnium alloy crankcase. A pressurized oil lubrication system was used and cooling was achieved with a water pump which circulated water around the cylinders from external pipes connected to a vertical tube radiator, rather than the evaporative open cooling water system with natural convection circulation that they had used in the 1903 design. There was no carburettor fitted as the metered fuel pump performed this function. The sole means of regulating engine speed was a spark advance pedal controlled by the pilot and connected to the high-tension ignition system which consisted of a Mea or Bosch magneto driven from the camshaft and spark plugs fitted to each cylinder. Like all Wright engines, the 1906 version featured a heavy external flywheel fitted to the end of the crankshaft. This basic four-cylinder design was later developed into six and eight-cylinder versions. Around 100 of these four-cylinder units were built in the United States, Germany and France.

Six of the Wright Model 'A' engines built under licence by Barriquand & Marré, of Paris, were fitted to Wright designed biplanes, built by Short Brothers Ltd, of Eastchurch, England, 1909-1910, under the first ever contract placed for the commerical production of aircraft.

References:

Anderson, John D. Jr, The Airplane - A History of Its Technology, American Institute of Aeronautics & Astronautics, 2002.

Hobbs, Leonard S., "The Wright Brothers' Engines And Their Design", Smithsonian Annals of Flight, No.5, Smithsonian Institution Press, Washington, 1971.

More Information

-

Keywords

-

Authors

-

Article types