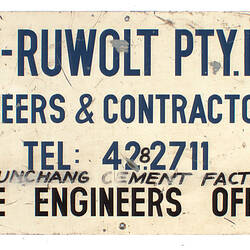

The Vickers Ruwolt Collection comprises over 1,700 glass plate negatives relating to production at the Vickers Ruwolt engineering works on Victoria Street Richmond, taken between 1915 and the late 1950s. It also includes a small selection of photographic prints, company publications and factory signage dating from the period between 1948 and 1986. The collection was donated to Museum Victoria by Vickers Ruwolt Pty Ltd between 1987 and 1989.

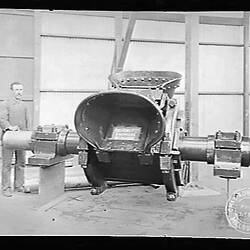

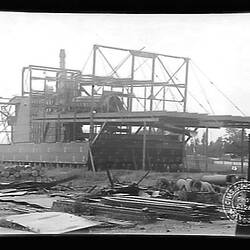

In 1902 the German-born and Australian educated engineer, Charles Ernest Ruwolt (1873-1946), opened an iron foundry and engineering works in Wangaratta for the purpose of manufacturing windmills and carrying out agricultural machinery repairs. By 1906, Ruwolt had diversified into repair work on bucket dredges and other gold mining equipment employed in the Ovens Valley, employing a workforce of 20 to 30. In 1908 Ruwolt merged his business with an engineering workshop in Bright owned by Isaac Stevenson, an experienced dredge engineer from New Zealand, and they commenced manufacturing complete gold and tin mining dredges. The firm was at this time registered under the title Charles Ruwolt Pty Ltd, with a working capital of £25,000, with Ruwolt and Stevenson as the principal shareholders.

In 1911, partially in response to a growing export demand for large tin mining dredges, Charles Ruwolt acquired a 10-acre site previously used for market gardens on the banks of the Yarra River in the Melbourne suburb of Richmond, with a view to relocating the company's manufacturing operations. Construction of engineering workshops, company offices and an iron and steel foundry commenced on the Richmond site in January 1912 and over the following few years all the firm's activties were progressively relocated to Richmond. By 1914, the registered office of Charles Ruwolt Pty Ltd had moved to Victoria Street, Richmond.

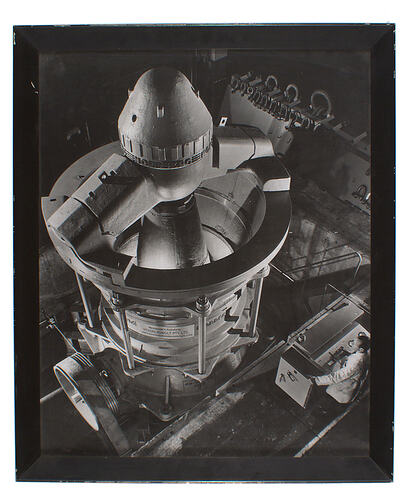

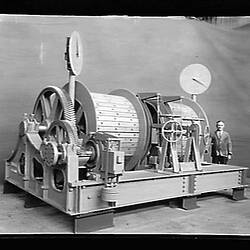

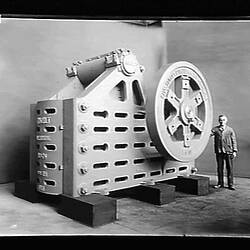

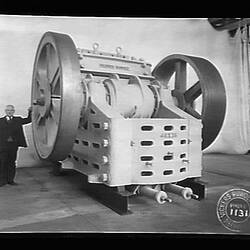

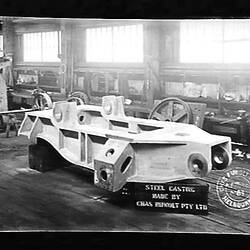

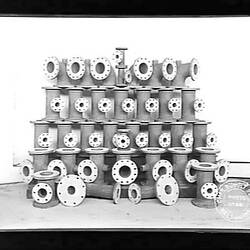

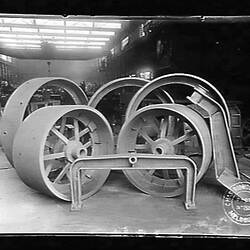

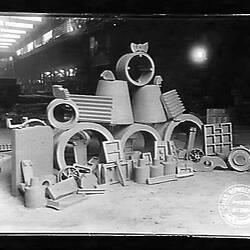

In November 1920, the firm was reorganised as a public company under the title Charles Ruwolt Proprietary Company Ltd. with a nominal captial £250,000, with additional shareholdings taken up two long-term employees Mr Arthur Irwin Beard and Mr Ellis H. Davies, and the founder's son Rupert Ruwolt, who also became directors. By 1922, the firm had began diversifying into heavy industrial work, producing road-making equipment, ore crushing machinery for the mining industry, brewing machinery and hydraulic presses for the emerging Australian car industry. By 1938, Ruwolts was one of the largest engineering companies in Australia, occupying 20 acres (8 hectares) and employing 600-700 workers. With the advent of the Second World War, the firm was deployed to manufacture field artillery and Charles Ruwolt held a senior position in the wartime administration of home-front resources.

Charles Ruwolt died in 1946 and by 1948 Vickers Limited (UK) had purchased the business, which then became Vickers Ruwolt Pty Limited. Later, Hoskins and HADWA, both companies in Perth, were purchased and a new public company, Vickers Australia Limited was formed. Vickers Ruwolt, a Division of Vickers Australia Limited, was over one-third owned by the Australian public and employed about 4,000 people around Australia. Between 1982 and 1983, the HADWA steel foundry in Perth and the Ruwolt steel foundry in Richmond were closed, and in 1985 it was decided to close the Ruwolt facility and move the heavy fabrication, machine and fitting factories to Karrabin, Queenland.

The material in the collection relates to the period from 1915 to the late 1960s, after the company had moved to Richmond and begun producing heavy industrial equipment. The images show the products produced by Ruwolt & Co, both in the factory and the field, and also depict the factory, its development and staff, during this period.

More Information

-

Keywords

Bucket Dredges, Building & Construction, Castings, Engineering Products, Engineering Works, Gold Dredges, Manufacturing, Apprenticeships, Engineering Industry, Foundries, Manufacturing Equipment, Manufacturing Works, Mining Machinery, Occupational Health & Safety, Road Making Machinery, Rock Crushers, Structural Steelwork, Trade Unions, Trades, Working Life

-

Authors

-

Article types