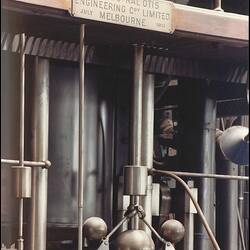

The year 2011 marks the centenary of the two oldest surviving Australian-built steam engines at the former Spotswood Pumping Station. Manufactured by the Austral Otis Engineering Company Limited, of South Melbourne, the engines were installed in Wells Number 7 & 8 in the North Engine House and were coincidently the 7th & 8th pumping engines installed at Spotswood.

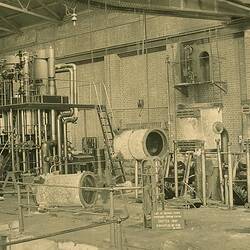

Rated at 300 nominal horsepower, the engines are of a type described as inverted vertical rotative triple-expansion direct-acting surface-condensing steam pumping engines, and were each capable of pumping 9 million gallons (40 million litres) of sewerage a day against a head of 125 feet (38.1 metres). They were amongst the most sophisticated reciprocating steam engines ever made in Australia and have advanced design features such as semi-rotary Corliss valves on all cylinders and improved Craig trip gear for steam cut-off.

In March 1909, the Melbourne & Metropolitan Board of Works advertised tenders for the "Manufacture (within the state of Victoria), Supply, Delivery, and Erection, in the Northern Engine House, at the Pumping Station, Spotswood, of two Pumping Engines, complete." Tenders closed on 25th May 1909, and on 15th June the tender of the Austral Otis Company was accepted at a cost of £19,830/17/8.

Although Austral Otis had supplied an earlier steam engine for the Spotswood Pumping Station in 1902, the design of Engines No.7 & 8 was based on Engine No.5, in the South Engine Room, which had been built by Hathorn Davey & Co Limited, of Leeds, in 1900 and had proved to be the most efficient of the first six engines installed. The Board of Works had obtained a full set of working drawings with the Hathorn Davey engine, but Austral Otis began its contract by preparing a new set of drawings, incorporating a number of modifications to the original design probably made as a result of the experience gained in installing and running the earlier engine. Amongst the changes made was the use of a massive single-piece bedplate casting for rigidity, additional crankshaft bearings and a modified governor controlling the steam cut-off on all three cylinders, rather than just the high-pressure cylinder.

Erection of the engines commenced in late 1910, with the installation of large beams 35 feet (10.7 metres) below ground to support the cast-iron pump casings and steam condenser, followed by the assembly of the engines themselves at ground level.

Engine No.7 was first run under steam on Monday, 8th May 1911, and after a month of further testing and adjustments was handed over to the Board of Works to begin its official 12-month warranty period on 6th June 1911.

Engine No.8 was first run on steam on Thursday, 28th September 1911, and was handed over to the Board of Works to begin its official 12-month warranty period on 12th October 1911.

When official duty trails of both engines were undertaken in July 1912 they performed admirably, both recording figures over 180 million ft-lbs per 1,120 lbs steam consumed - equivalent to 20% over manufacturer's guarantee and 6% better than the original Hathorn Davey engine. The completion of the engines was a triumph for Victoria's local engineering industry, however, after a glowing account of the duty trials was published in the British journal Engineering, it is interesting to note that in the following issue a letter from the manager of Hathorn Davey & Co's Sun Foundry, Leeds, was published politely pointing out that the plant described 'corresponds almost exactly' with 'a sewerage pumping plant designed and constructed by ourselves for the Melbourne and Metropolitan Board of Works in 1900' and further commenting that:

'During the twelve years that have elapsed since we designed the Melbourne engine considerable progress has been made. Superheated steam is now generally adopted, with a consequent economy in fuel, and so many mechanical details have been simplified or improved as to materially improve the durability and efficiency of the whole.'

'As an instance of this improvement we may mention the four engines designed and constructed for the Rand Water Board in 1906 ... [which] showed a duty ... of 210 millions, compared with the 184.8 in your report.'

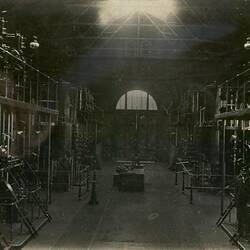

Pumping Engines Nos.7 & 8 continued to operate at the Spotswood Pumping Station until 1947, although most of their work was done prior to the installation of the first generation of electric pumps in 1921-23. During these years the use of the engines peaked at around 40-68% of the total number of hours in a year. After they were retired, the engines sat quietly in the southern corners of the North Engine House silently gathering dust, but were given an occasional polish by the pumping station staff.

In 1982, Engine No.8 was modified by the Board of Works engineering staff to operate on compressed air for demonstration purposes and it continues to be run on a daily basis as a feature of guided tours through the Pumping Station. In March 1989, Museum Victoria took over the management of the former Spotswood Pumping Station and the Austral Otis steam engines.

More Information

-

Keywords

-

Localities

-

Authors

-

Article types