Summary

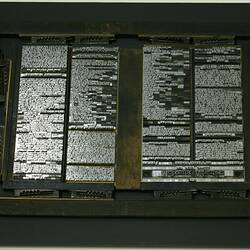

Roller for use using a hand press. The roller was used to thin the thick printing ink before it was applied to the type.

This was done on the top surface of a stone or on the stone surface of an inking table. ( A 'stone' could be made of iron too).

The upper flat surface of the stone held the thick printers' ink. An amount of ink was placed at the top or corner of the stone and was spread out across the stone, thinning it out. This was called 'braying'.

Originally, the braying was carried out using a muller, a flat bottomed wooden hand tool. - the muller is also referred to as a "brayer".

The flat-bottomed wooden brayer was eventually replaced by a roller.

When thinned out, ink balls or rollers were worked across the stone to pick up the ink and they were then worked across the type on the press in a dabbing or 'beating' motion to prepare it for printing.

Physical Description

Round roller attached to a metal bracket which is connected to a wooden handle.

More Information

-

Collecting Areas

-

Acquisition Information

Unknown Acquisition Method from Museum Victoria

-

Date Made

-

Classification

-

Category

-

Discipline

-

Type of item

-

Object Measurements

24 cm (Length), 30 cm (Width), 8.5 cm (Height)

-

Keywords