Summary

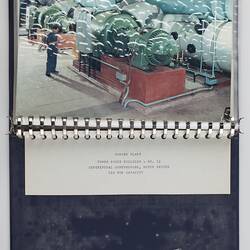

Colour photograph of a Power House operator checking the operation of one of two electrical motor driven centrifugal refrigeration compressors located in the Machinery Hall of the Power House, Building 11, at the Kodak factory, Coburg, circa 1963.

The Power House, Building 11, at the Coburg Factory consisted of an integrated Machinery Hall with its north and south annexes, Boiler Hall, evaporative water cooling towers, 62 metre brick chimney stack, oil bunkers, tank farm and office/amenities block. The fully integrated Power House provided the most efficient use of electricity and fuel oil (and later natural gas) to match the variable load of the factory.

The two electrical motor driven centrifugal refrigeration compressors shown in the photograph were located in the Machinery Hall. They were each rated at 1.6MW (450 Ton) and provided chilled water at 3ºC for cooling and air conditioning throughout the Coburg site. Along with three temporary packaged steam boilers, these chillers were the first equipment to be installed in the Machinery Hall for the factory start-up period 1958-60. Following the planned building of the Boiler Hall and the installation of two oil-fired boilers during 1960-61 to cope with the expanding factory, these chillers formed part of the tightly integrated heating, cooling and electrical equipment of the Power House.

The two 4.5 Kg/s oil-fired boilers generated super-heated steam to 400ºC at 3.1MPa. The steam passed through two Allen back pressure steam turbine driven alternator sets (one triple-expansion & one double-expansion), rated at 1.2 MW and 0.5 MW respectively (415 V, 50Hz. The steam also passed through a back pressure steam turbine driving a Worthington centrifugal refrigeration compressor rated at 3MW (850 Ton), providing 3ºC chilled water for cooling and air-conditioning throughout the factory. The electricity generated represented the power requirements to maintain essential services throughout the factory (the rest being supplied off the Preston City Council grid). There was no interconnection between the electricity systems but individual buildings could be switched to either supply as desired.

The low pressure steam (70 KPa) from the turbine passouts was circulated throughout the factory site in an overhead reticulation system which was lagged and clad for protection and efficiency. Excess low pressure steam, which was not required for heating during summer, was passed through a low pressure fully condensing steam turbine driving another Worthington centrifugal refrigeration compressor also rated at 3MW (850 Ton). This provided additional chilled water capacity. In addition, the two electrical motor driven 1.6MW (450 Ton) centrifugal refrigeration compressors shown in the photograph, provided additional capacity to cope with low excess steam or very heavy cooling loads. Maximum efficiency of generation and use of the steam was achieved by balancing the local/grid electrical usage and heating/cooling requirements of the factory over the summer and winter loads. All of this plant was in use until the factory closed in 2004.

Kodak manufactured and distributed a wide range of photographic products to Australasia, such as film, paper, chemicals, cameras and miscellaneous equipment. Its client base included amateur and professional photographers, as well as specialist medical and graphic art professionals who used photography, x-ray and other imaging techniques.

This photograph is part of the Kodak collection of products, promotional materials, photographs and working life artefacts collected from Kodak Australasia in 2005, when the Melbourne manufacturing plant at Coburg closed down.

Description of Content

Photograph of a series of turbines in a factory interior. A man wearing blue overalls is standing in front of one of the turbines and is monitoring the equipment and writing observations on a clipboard.

Physical Description

Colour photograph printed on medium weight Kodak paper, landscape format.

More Information

-

Collection Names

-

Collecting Areas

-

Acquisition Information

Donation from Kodak (Australasia) Pty Ltd, Ms. Kate Metcalf - Kodak (Australasia) Pty Ltd, 2005

-

Acknowledgement

Courtesy of Kodak (Australasia) Pty Ltd.

-

Place & Date Depicted

Coburg, Greater Melbourne, Victoria, Australia, 1962-1963

Ritter-Jeppesen took photographs either January 1962 or 1963. -

Organisation Depicted

Kodak (Australasia) Pty Ltd, Elizabeth Street, Coburg, Greater Melbourne, Victoria, Australia, 1962-1963

Ritter-Jeppesen took photographs either January 1962 or 1963. -

Photographer

Ritter-Jeppesen Studios Pty Ltd, Coburg, Greater Melbourne, Victoria, Australia, circa 1963

Ritter-Jeppesen took photographs either January 1962 or 1963. -

Format

Photograph, Colour

-

Inscriptions

Card insert, typed, black ink: 'COBURG PLANT/ POWER HOUSE BUILDING - NO.11/ CENTRIFUGAL COMPRESSORS, MOTOR DRIVEN/ 450 TON CAPACITY'

-

Brand Names

-

Classification

Manufacturing & industry, Photographic products, Factory interior views

-

Category

-

Discipline

-

Type of item

-

Image Dimensions - Photograph

241 mm (Width), 194 mm (Height)

-

Keywords

Compressors, Factories, Manufacturing Plants, Photography, Power Houses, Making History - Kodak Collection