Summary

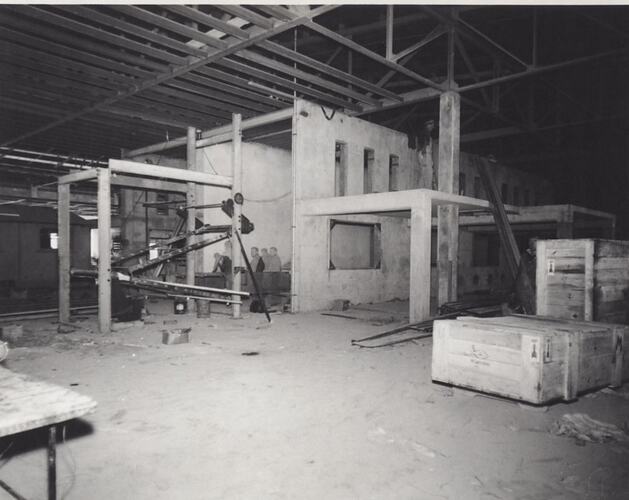

Black and white silver gelatin photograph taken inside Building 3, Emulsion Coating, and looking north-east towards the end of the Coating Track, Kodak factory, Coburg, May 1959.

This is a view of the winder storage magazine being assembled at the west end of the dryer section of the Coating Track. The Coating Track consisted of four sections. The first section was a continuous film or paper base conveyancing system, where a discrete master roll of base could be mounted on an unwinding machine and storage magazine, then spliced to the previous roll without stopping the coating process. It was then conveyed through the continuous coating process with correct tension and steering, and finally through a storage magazine and winding machine where it could be separated from the following roll, and unloaded as a discrete roll without stopping the coating process. The second section was a coating station where previously prepared emulsion taken from the emulsion store, melted to liquid consistency, along with any final additional chemicals, was coated onto the film or paper base by a proprietary method. The third section was an air chiller section where the liquid emulsion was set onto the base. And finally, the fourth section was an air dryer section where the emulsion was dried and conditioned sufficiently to enable the base to be rolled up under tension without damaging the emulsion surface.

The winder storage magazine had essentially a double acting scissor type motion whereby two pairs of arms (each with a dozen idle rollers) rotated about axles at opposite ends of the frame. The free ends of each arm were connected by a chain and sprocket system, maintaining a constant parallel positioning of the arms to each other. The bottom arms were weighted to maintain a certain level of base tension, and could be altered manually depending on the product. Feed in and feed out rates were determined by suction roll drives before and after the magazine. The feed in rate matched the coating track speed whilst the feed out rate depended on the actions being carried out at the winder, for example, when the winder was stopped to unload a full roll and splice the base end on to a new roll core, the suction roll drive was stopped and the magazine began to fill; similarly, when the base started to wind on a new core, the suction roll drive went into overdrive in order to empty the magazine.

Kodak manufactured and distributed a wide range of photographic products to Australasia, such as, film, paper, chemicals, cameras and miscellaneous equipment. Its client base included amateur and professional photographers as well as specialist medical and graphic art professionals who used photography, x-ray and other imaging techniques.

This photograph is part of the Kodak collection of products, promotional materials, photographs and working life artefacts collected from Kodak Australasia in 2005 after the manufacturing plant at Coburg had closed down the year before.

Description of Content

Image of tradesmen standing at one end of the open concrete structure of the coating track dryer, viewing the assembly of a magazine mechanism within a steel frame. The coating track is being built under the roof structure of the large open spaced interior of the west wing of Building 3.

Physical Description

Black and white silver gelatin photograph printed on light weight paper, landscape format.

More Information

-

Collection Names

-

Collecting Areas

-

Acquisition Information

Donation from Kodak (Australasia) Pty Ltd, Ms. Kate Metcalf - Kodak (Australasia) Pty Ltd, 2005

-

Acknowledgement

Courtesy of Kodak (Australasia) Pty Ltd.

-

Place & Date Depicted

-

Organisation Depicted

Kodak (Australasia) Pty Ltd, Coburg, Greater Melbourne, Victoria, Australia, May 1958

-

Format

Photograph, Black & White

-

Inscriptions

Back, stamp: 'KODAK ABBOTSFORD/TESTING DEPARTMENT PHOTOGRAPH/20 MAY 1959 Reference No. 59007D'

-

Classification

Manufacturing & industry, Photographic products, Factory interior views

-

Category

-

Discipline

-

Type of item

-

Image Dimensions - Photograph

253 mm (Width), 202 mm (Height)

-

Keywords

Building & Construction, Buildings, Factories, Manufacturing, Photography, Making History - Kodak Collection