Summary

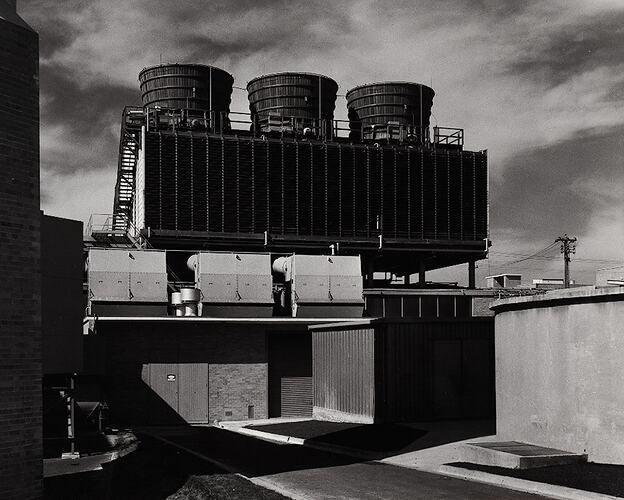

Black and white silver gelatin photograph taken by Wolfgang Sievers features the evaporative water cooling towers of Building 11, Power House, at the Kodak Australasia Pty Ltd factory complex in Coburg, 1964.

This view of the west end of the Power House looking from the north shows the Marley evaporative cooling towers located above the Machinery Hall, three cooling water units for the brine refrigeration compressors mounted above the North Annexe building, and in the foreground, two concrete water tanks on the right and the base of the chimney stack on the left.

The Power House Building 11 at the Coburg Factory consisted of an integrated Machinery Hall with its north and south annexes, Boiler Hall, evaporative water cooling towers, 62 metre brick chimney stack, oil bunkers, tank farm and office/amenities block.The fully integrated Power House provided the most efficient use of electricity and fuel oil (and later natural gas) to match the variable load of the factory. For its time in the early 1960s, this plant represented best practice in engineering design, construction and use of energy conversion.

There were three separate evaporative water cooling units within the one tower structure, each with its centrifugal fan and venturi outlet and racks of louvred timber over which the water was sprayed for air cooling. Under certain seasonal conditions there was sufficient redundancy in the cooling capacity to allow each unit to be serviced separately. These towers provided cooled water for the turbine and refrigeration condensers at up to 800 litres per second.

The North Annexe of the Machinery Hall contained a control room for the fire pumps and factory sprinkler systems and some of the compressors for both compressed air and ethylene-glycol (brine) refrigeration. The brine refrigeration system used two screw and three multi-cylinder reciprocating ammonia compressors circulating brine at an outgoing temperature of -9ºC. These five units totalled 2.1 MW to service chill rooms, low dew-point drying and emulsion chilling, and to cope with summer load conditions. Compressed air supplied from four compressors was circulated throughout the factory at 550 KPa up to 1150 litres per second. These were all non-lubricated units using dry carbon or teflon piston rings and seals so that the compressed air was free from any contamination.

Large quantities of treated and clarified water was used in the manufacturing areas particularly in emulsion and photochemical operations. Incoming mains water was first passed through sand filters and stored in tanks for immediate use or for further chemical treatment and subsequent storage in the tank farm area north of the North Annexe. Two 455,000 litre concrete water tanks were reserved for the fire pumps and provided sufficient capacity to deal with a prolonged major fire incident. Large quantities of distilled water was used in emulsion making and testing. This water was distilled to a purity of 0.3 microsiemens in two triple-effect stills (and later in reverse-osmosis filters) located in the Machinery Hall. With a total production capacity of 2300 litres per second this water was stored in a 27 kilolitre stainless steel tank and reticulated throughout the factory in Pyrex glass piping.

All of this plant was in use until the factory closed in 2004.

Wolfgang Sievers is widely recognised as one of Australia's most significant architectural and industrial photographers. He pioneered a modernist photographic style influenced by the Bauhaus, and his work celebrates industry and the worker. Sievers was commissioned to document the newly constructed Kodak Coburg plant. He subsequently took several hundred black & white and colour images that highlighted the modern architectural and industrial design features of the complex.

Kodak manufactured and distributed a wide range of photographic products to Australasia, such as film, paper, chemicals, cameras and miscellaneous equipment. Its client base included amateur and professional photographers, as well as specialist medical and graphic art professionals who used photography, x-ray and other imaging techniques.

This photograph is part of the Kodak collection of products, promotional materials, photographs and working life artefacts collected from Kodak Australasia in 2005, when the Melbourne manufacturing plant at Coburg closed down.

Description of Content

The photograph features a view from the north emphasising the evaporative water cooling towers. In the right foreground are two concrete water tanks. The shadow from the chimney stack can be seen to the left of the photograph.

Physical Description

Black and white, silver gelatin photograph printed on light weight paper, landscape format.

More Information

-

Collection Names

-

Collecting Areas

-

Acquisition Information

Donation from Kodak (Australasia) Pty Ltd, Ms. Kate Metcalf - Kodak (Australasia) Pty Ltd, 2005

-

Acknowledgement

Courtesy of Kodak (Australasia) Pty Ltd.

-

Place & Date Depicted

Coburg, Greater Melbourne, Victoria, Australia, 1964

For date see HT 20552, Invoice - Photography, Wolfgang Sievers Pty Ltd to Kodak Australasia Pty Ltd, 28 Aug 1964 -

Organisation Depicted

Kodak (Australasia) Pty Ltd, Coburg, Greater Melbourne, Victoria, Australia, 1964

-

Photographer

Wolfgang G. Sievers AO, Coburg, Greater Melbourne, Victoria, Australia, 1964

-

Format

Photograph, 8" x 10", Black & White

-

Inscriptions

Back, stamp: 'WOLFGANG SIEVERS/Photographer/9 COLLINS ST., MELBOURNE C.1./TELEPHONE 63-4021' Back, handwritten, pencil: '3362F'

-

Classification

Manufacturing & industry, Photographic products, Factory exterior views

-

Category

-

Discipline

-

Type of item

-

Image Dimensions - Photograph

244 mm (Width), 197 mm (Height)

-

References

Beale, N, The History of Kodak in Australia, Coburg, no date. [Link 1] "A Brief Process Based Site History, Kodak (Australasia) Pty Ltd, Coburg Plant" Kodak (Australasia) Pty Ltd, 2007 Pamphlet, "Milestones in the History of Kodak (Australasia) Pty. Ltd", Kodak (Australasia) Pty. Ltd., 1985 Leggio, Angeletta "A History of Australia's Kodak Manufacturing Plant", Topics in Photographic Preservation, Volume Twelve, 2007 Ennis, Helen "Intersections: Photography, History and the National Library of Australia", National Library of Australia, Canberra, 2004

-

Keywords

Cooling Towers, Exterior Views, Factories, Manufacturing Plants, Photography, Power Houses, Making History - Kodak Collection