Summary

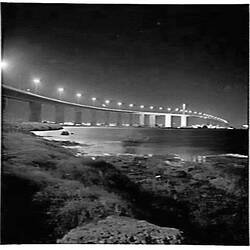

The West Gate Bridge was constructed by the Lower Yarra Crossing Authority between 1968 and 1978, linking the City of Melbourne directly to its western suburbs. Measuring 2.59 km in overall length, the steel and concrete bridge rises to a maximum clear height of 53.6 m above low water level and carries six lanes of traffic on a 37 m wide deck. At the time of completion it was the largest bridge in Australia and is a major Melbourne landmark, providing a key east-west crossing of the lower Yarra River that carries up to 200,000 vehicles a day. Yet even before its completion was heralded as an engineering triumph, the West Gate Bridge had gained worldwide attention due to a tragic accident that occurred during construction, when a 117 m long section collapsed at 11:50 am on 17 October 1970, killing 35 men and seriously injuring 18 others. It was Australia's worst non-mining industrial accident.

The Royal Commission into the Failure of the West Gate Bridge, chaired by Mr Justice Barber, commenced on 28 October 1970. The Commission collected evidence from 52 witnesses and sat for 73 days - broken only for Christmas and Easter. Hearings were concluded in May 1971 and the report was submitted on 14 July 1971, being presented to the Victorian Parliament on 3 August 1971. In their introduction the Royal Commissioners attributed blame for the collapse of the bridge to an unfortunate sequence of events to which all parties involved in the construction were in part responsible:

'There can be no doubt that the particular action which precipitated the collapse of span 10-11 was the removal of a number of bolts from a transverse splice in the upper flange plating near to mid-span. The bolts were removed in an attempt to straighten out a buckle which had occurred in one of the eight panels which constitute the upper flange. The buckle in turn, had been caused by the application of kentledge in an attempt to overcome difficulties caused by errors in camber.

To attribute the failure of the bridge to this single action of removing bolts would be entirely misleading. In our opinion, the sources of the failure lie much further back; they arise from two main causes.

Primarily the designers of this major bridge, Freeman Fox and Partners, failed altogether to give a proper and careful regard to the process of structural design. They failed also to give a proper check to the safety of the erection proposals put forward by the original contractors, World Services and Construction Pty Ltd. In consequence, the margins of safety for the bridge were inadequate during erection; they would also have been inadequate in the service condition had the bridge been completed.

A secondary cause leading to the disaster was the unusual method proposed by WSC for the erection of spans 10-11 and 14-15. This erection method, if it was to be successful, required more than usual care on the part of the contractor and a consequential responsibility on the consultants to ensure that such care was indeed exercised. Neither contractor, WSC nor later John Holland & Co, appears to have appreciated this need for great care, while the consultants FF & P, failed in their duty to prevent the contractor from using procedures liable to be dangerous.'

The donor of this report worked as a young engineer for the team that investigated the causes of the bridge collapse and was subsequently involved in the reconstruction work.

Physical Description

Cloth tape and stitch-bound 144 page foolscap-sized portrait-format book of 144 pages with light brown textured cardboard covers. Contents printed in black on off-white paper stock.

More Information

-

Collection Names

-

Collecting Areas

-

Acquisition Information

Donation from Prof David M. Young - University of Melbourne, 2009

-

Printer

C.H. Rixon, Government Printer, Melbourne, Greater Melbourne, Victoria, Australia, 1971

-

Past Owner & User

Prof David M. Young - University of Melbourne, University of Melbourne, Parkville, Greater Melbourne, Victoria, Australia, circa 1971-2009

-

Inscriptions

Cover Text: '1971 / VICTORIA / REPORT / OF / ROYAL COMMISSION / INTO THE / FAILURE OF / WEST GATE BRIDGE / PRESENTED TO BOTH HOUSES OF PARLIAMENT PERSUANT TO SECTION 7 OF THE / WEST GATE BRIDGE ROYAL COMMISSION ACT 1970, No. 7989 / By Authority / C. H. RIXON, GOVERNMENT PRINTER, MELBOURNE. / 7037/71.-PRICE $1.90. Signed: 'DMYoung' in red ball-point pen near top right-hand corner and below same stamped: '[logo] I.E.Aust /David M. Young / PIEAust CPEng / Chartered Professional Engineer / Membership No. 309008 / The Institution of Engineers Australia.'

-

Classification

-

Category

-

Discipline

-

Type of item

-

Overall Dimensions

212 mm (Width), 8 mm (Depth), 338 mm (Height)

-

Keywords

Bridge Construction, Civil Engineering, Concrete Bridges, Disasters, Metal Bridges, Road Bridges, Royal Commissions