Summary

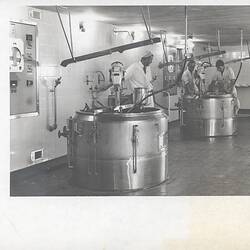

The Finishing Room was on the first floor of Building 2 and features a steel reinforced concrete floor, columns and ceiling. The floor is finished with glazed ceramic tiles and drainage holes. Two (of three) water-jacketed stainless steel emulsion kettles can be seen mounted on the floor, along with the kettles' respective control panels on the wall.

Batches of emulsion were first made in Making Kettles where chemicals, silver nitrate, gelatin and halide salts were added into distilled water under a strictly controlled regime of mixing and temperature conditions. After setting and shredding, excess nitrates were washed out with treated water and passed on to the Finishing Kettles. Here further chemicals and gelatin were added under strictly controlled mixing and temperature conditions. Each emulsion batch was then run off into stainless steel cans, cooled, weighed and stored ready for use in the coating operations. Each batch was sampled for trial coatings and sensitometry, and from these results larger batches would be made by blending the smaller batches to make sufficient emulsion for a coating run.

This photograph is part of the Kodak collection of products, promotional materials, photographs and working life artefacts collected from Kodak Australasia in 2005, when the Melbourne manufacturing plant at Coburg closed down.

Description of Content

Two large stainless steel vats are mounted onto the glazed tiled floor. The vat in the foreground features a large mixer and several pipes around the outside. A pipe from the ceiling is positioned inside the opening at the top of the vat. The wall beside it features a control panel. A man wearing white protective clothing is standing beside the vat and looking at two men standing at the second vat behind him. The two men are wearing white overalls. The set up for this vat is similar to the one in the foreground.

Physical Description

Black and white photographic print, lightweight paper with white border.

More Information

-

Collection Names

-

Collecting Areas

-

Acquisition Information

Donation from Kodak (Australasia) Pty Ltd, Ms. Kate Metcalf - Kodak (Australasia) Pty Ltd, 2005

-

Acknowledgement

Courtesy of Kodak (Australasia) Pty Ltd.

-

Organisation Depicted

Kodak (Australasia) Pty Ltd, Elizabeth Street, Coburg, Greater Melbourne, Victoria, Australia, circa 1965

-

Format

Photograph, Black & White

-

Classification

Manufacturing & industry, Photographic products, Factory interior views

-

Category

-

Discipline

-

Type of item

-

Image Dimensions - Photograph

253 mm (Width), 202 mm (Height)

-

Keywords

Factories, Manufacturing, Photography, Manufacturing Processes, Kettles, Workers