Summary

Single H-type briquette, produced for domestic or household use. Sample from the earliest production at the State Electricity Commission's Yallourn Briquette Works, situated in the Latrobe Valley, near Morwell, Victoria, dated circa 1925 (or 1929?). Manufactured from brown coal extracted in the adjacent Yallourn Open Cut Coal Mine. Construction of the Yallourn Briquette Works commenced in mid-1922, using primarily imported German technology and equipment.The plant began trial runs in mid-November 1924 and commerical sales of briquettes commenced in February 1925, with production reaching 350 tons/day by mid-1926.

H-type briquettes were the largest form of briquette made by the SECV, being pressed as a 10-inch (254 mm) long two-piece block or bar, joined in the middle by a narrow waist, which allowed the bar to be easily broken into two pieces or individual briquettes, each of a convenient size and weight to be picked up by hand. H-type briquettes were designed to be used as a domestic fuel, in hand-fired open-grate fires, space heaters, solid-fuel stoves and hot water heaters. At manufacture there were approximately 2,600 H-type briquettes to the ton, with each briquette weighing about 13¾ oz. (390 g).

Part of an original sample presented by the State Electricity Commission, 17 Jul 1931, comprising one co-joined double block (now broken into two pieces) and four single briquettes of the same size. This piece one of the four individual briquettes, others now registered separately as HT 16834, HT 16835, and HT 56108. Originally registered as part of ST 018405, which number is now reserved for the double H-type sample.

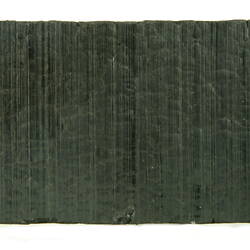

Physical Description

Dark browny/black in colour with hard glossy surface and relatively light in weight. One half of a double briquette bar, originally pressed as two conjoined briquettes in a single block, measuring 10-inch x 2½-inch x 1¾-inch overall, with a narrow waist band in the middle allowing the block to be broken into two equal pieces. Sample has square corners on the outer end and rounded corners adjacent to what was originally the central waist. A letter from the Electricity Commission, dated 30 Jun 1931, gave the following general analysis for briquettes manufactured at Yallourn (the quality of which was standardised in the course of manufacture): Moisture - 14.00 % ; Volatile Matter - 42.40 % ; Fixed Carbon - 41.75 % ; Ash - 1.85 % ; -------------- Total 100.00 % -------------- Calorific value by bomb calorimeter was 9500 B.T.U. (gross) per lb. [See back of Registration Card for RN 018405].

More Information

-

Collecting Areas

-

Acquisition Information

Donation from Publicity Division, State Electricity Commission of Victoria (SECV), 17 Jul 1931

-

Place & Date Manufactured

Yallourn Briquette Works, State Electricity Commission of Victoria (SECV), Yallourn, Latrobe Valley, Gippsland, Victoria, Australia, circa 1925

-

Inscriptions

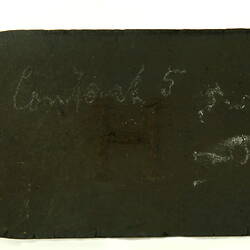

Impressed with the label 'H' as a raised letter on one face and indented letter on the other face. Markings read: 'Cont?out 5' and '12/4 29' [possibly records date of manufacture]

-

Classification

-

Category

-

Discipline

-

Type of item

-

Overall Dimensions

128 mm (Length), 62 mm (Width), 41 mm (Height), 362 g (Weight)

Broken remains of neck 25 mm wide x 41 mm high.

-

Keywords