Summary

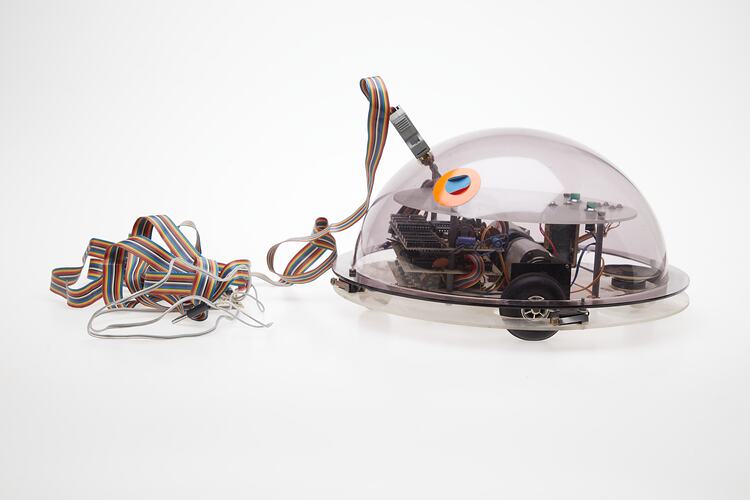

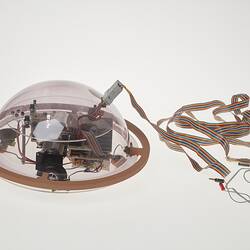

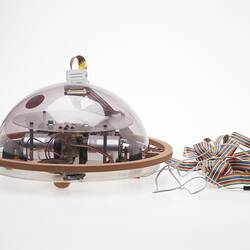

Educational computerised, tethered floor-roving robot, made by Denning Branch International, Hobart, Tasmania, 1982. It uses LOGO programming language advocated by Seymour Papert.

Denning Branch International, was the trading name for Branch & Associates. The Tasman Turtle was an easily controlled mobile robot which could 'feel' with its touch sensors and could 'talk' with its speech board. It featured speech recognition, speech sysnthesis, electronic compass, touch sensors, drawing pen, stepper motor motion control, infra-red and expansion ports.

The turtle as related to Turtle Geometry, a new field of mathematics enabled by the control of an object (physical or screen) using a computer program. At the time the notion of 'concreteness' was considered of great importance - young children 'apparently' needed physical objects, 'concrete' objects, to interact with. In some schools this meant cuisenaire rods for learning about numbers. In the Sunrise School, children controlled screen and physical objects using Logo programming. It was felt there was no difficulty for them in considering the screen object, at the time a tiny triangle, in the same way as they did the physical object. They happily called the screen object a turtle and talked to it as they would a toy. This issue was pertinent to the development of new ways of representing geometry but did not satisfy everyone. Nevertheless, millions of children who used Logo around the world did not have access to such things as a physical robot but still worked and were comfortable with their 'turtle' and learnt Turtle Geometry.

This Tasman Turtle was owned and used by Dr. Liddy Nevile in her student research and classroom work in the 1980s. This object forms part of the Sunrise Collection which includes educational robots, software and multimedia recordings of teachers and students mainly in Victoria exploring new possibilities with computer programming.

Physical Description

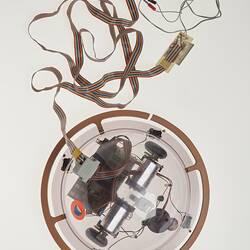

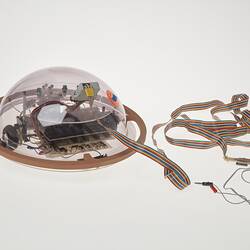

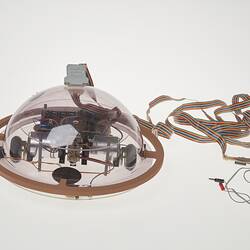

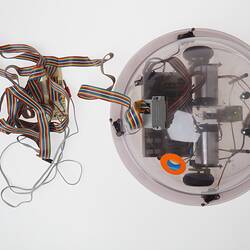

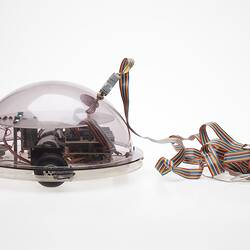

The robotic toy comprises a hemispherical case of transparent grey acrylic with a flat flange, to which a clear circular acrylic base, separated by a 15 mm gap, is joined at four points on the periphery with bakelite and spring-steel bump sensors. There is a small triangular label with a green logo and black, printed text on the top surface of the base. A freely-moving, light-brown moulded plastic ring, approximately 40 mm larger in diameter than the domed case, is positioned in the gap above the base. The ring is broken at one point and a short strip of green pastic tape is stuck at one side of the break. There are two black rubber wheels protruding through slots in the base and two domed timber supports joined to the base with metal screws. Internally there are two metal-cased motors, one to each wheel; a stack of three microprocessor circuit boards, multi-coloured cables and wires, a small speaker and two green and four red light-emitting diodes. A 25-pin male 'D-shape' connector socket is fixed near the top of the domed case. A circular shape 45 mm diameter of bright orangle plastic, with a superimposed smaller circle of blue paper, is fixed to the outer surface of the domed case.

More Information

-

Collection Names

-

Collecting Areas

Information & Communication, Childhood, Social Spaces & Youth

-

Used By

-

Manufacturer

-

Date Made

1982

Similar model exits at Powerhouse dated 1982, which was aquired at time of manufacture. -

Inscriptions

Label on base: 'TASMANIA / [logo] / We made it!'

-

Classification

-

Category

-

Discipline

-

Type of item

-

Object Dimensions

175 mm (Height), 385 mm (Outside Diameter)

-

Keywords

Robots, Robotics, Robot Components, Computers, Computer Software, Computer Games, Computer Peripherals, Electronic Learning Aids, Education Programs, Education Kits, Educational Technology, Schools, Technology, Education, microworlds, constructionism