Summary

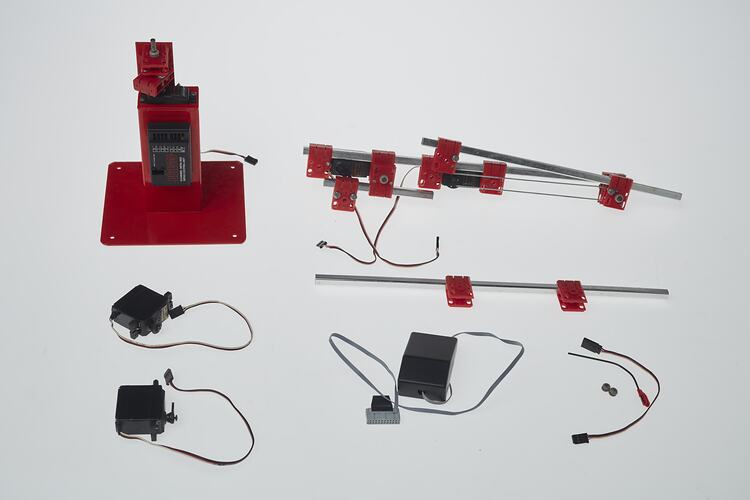

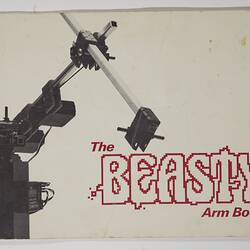

Robotic arm base and servo control module for the 'Beasty' robotic arm, manufactured by Commotion Ltd, Enfield, England, circa 1985.

This computer-contolled robotic arm was designed for school and home users by Micro-Robotics Cambridge, England. The 'Beasty' arm package comprised an arm mechanism, a computer interface and software, and the servo motors that could be assembled and programmed by a user.

As the time of its release in the UK, Dr. Bill Tagg, the Head of AUCBE, Advisor Unit for Computer Based Education in the UK, noted that he wouldn't consider it a robot unless it could be programmed to make a cup of tea, which it could.

The components include:

- metal base or stand

- infra-red servo control unit

- servo motors with leads and connection plugs

- lead to connect to a computer

- aluminium rods and connecting brackets to form short and longer top arms and a forearm

- software cassette

- handbook

- associated link rods, screws, bolts, washers and tape for its assembly.

This object forms part of the Sunrise Collection which includes educational robots, software and multimedia recordings of teachers and students, mainly in Victoria, exploring new possibilities with computer programming.

Physical Description

A red-painted metal base comprising two parts joined by two small bolts with hexangon-headed nuts, a flat square base with a hole in each corner, and a rectangular hollow tube upright. The tube is capped with a metal plate with an oblong cutout and four screw-holes, which is welded to the tube. Part of this end-cap is bent at a right angle and has a hole in each of its top corners. A black plastic-encased 8-channel infra-red control unit is fixed to the side of the rectangular tube with tape and a black plastic-encased servo motor is fixed with two screws in the oblong cutout in the end-plate of the tube with a length of red, white and blue lead with a connecting plug projecting from the top of the stand. Two red plastic brackets supporting a steel axle are fixed to the upstand of the tube capping and to the servo motor with steel self-tapping screws. There is a label with printed text fixed to the servo motor and another to the control unit.

More Information

-

Collection Names

-

Collecting Areas

Information & Communication, Childhood, Social Spaces & Youth

-

Used By

-

Manufacturer

-

Designer

-

Inscriptions

Label on control unit: 'MADE IN ENGLAND / BEASTY / 8 CHANNEL INFRA-RED / SERVO CONTROL UNIT' Connector ports numbered: '0 / 1/ 2/ 3/ 4/ 5/ 6/ B7 ' Label on servo motor: 'Futaba / FP-S128 / INDIRECT DRIVE'

-

Classification

-

Category

-

Discipline

-

Type of item

-

Maximum dimensions

150 mm (Length), 145 mm (Width), 200 mm (Height)

-

Keywords

Robots, Robotics, Robot Components, Computers, Computer Software, Computer Games, Computer Peripherals, Electronic Learning Aids, Education Programs, Education Kits, Educational Technology, Schools, Technology, Education, Publications, microworlds, constructionism