Summary

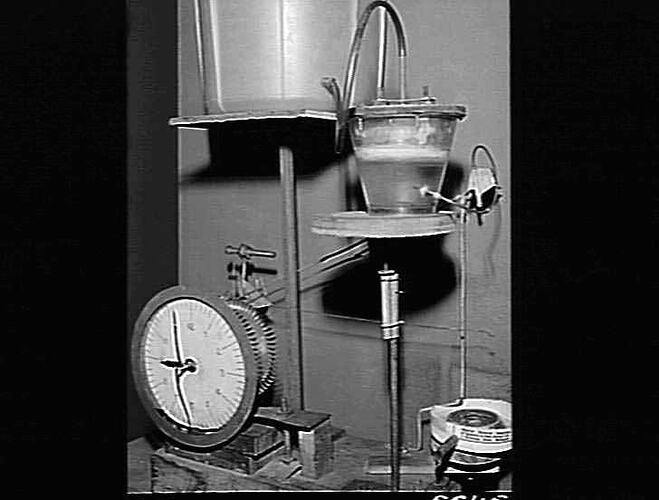

Water clock designed and made by Captain Edwin S. Nurse, Heathmont, Victoria, Australia, 1968.

Edwin Nurse retired from the Royal Australian Navy in 1956 after 40 years as a mechanical engineer. He spent his retirement inventing mechanical devices and described himself as a 'gadgeteer'.

This home-made water-driven pendulum-controlled clock has been made from readily available materials, using hand tools and a soldering iron. The weight of the water carries the horizontal pendulum down, which then discards the water and springs back to its original position. The clock is not compensated for temperature and is accurate to approximately one minute per day.

There are only three wheels, all of the same size with 60 teeth, cut from aluminium sheet with tin snips and a pair of pliers. The bearings for the wheel spindles and two cams are made from bent galvanized iron wire. A constant head of water to the 'dripping point' is maintained by a smaller 'constant level' tank, which is controlled by a float.

Physical Description

A large plastic container is connected by a rubber tube to a constant level reservoir that delivers a drop of water to the end of a horizontal pendulum. The pendulum falls and moves a cog attached to the second hand. Two other cogs and ratchets operate the minute and hour hands. The water drop falls into an outlet container so the pendulum rises again.

Significance

This is a unique water driven clock invented by Captain Edwin S. Nurse, R.A.N. (Retired) of Heathmont, Victoria. As far as can be ascertained this method of drive and the mechanism are unlike anything else in the world.

The clock is operated by a pendulum which is driven by drops of water. (This pendulum picks up a drop of water on its arm and this extra weight provides the power to operate the clock.) The energy of the swinging pendulum is transmitted by means of a ratchet operating on a toothed wheel. The gear train of the clock is very simple, consisting of three wheels of sixty teeth each mounted on co-axial shafts connected to the hands,. A cam on the back of the second wheel operates on a ratchet to move the minute hand one division each revolution of the second hand. Five cams on the minute wheel operate a ratchet to drive the hour hand (at its correct speed). To reduce friction the pendulum bearings are of the rolling type, the wire rolling (not rubbing) on its supports.

A feature of this clock is that it may be made in any home by a suitably skilled person equipped with a soldering iron, tin-snips and a pair of pliers. Captain Nurse designed the clock with this in mind using easily obtained materials. The wheels are cut from aluminium sheet and the teeth twisted through ninety degrees by hand using pliers. Much of the mechanism is cut from wire.

The rate of water flow is adjusted to provide, as nearly as possible, one water drop for each pendulum swing. This flow is adjusted by setting the height of a valve-controlled constant level reservoir to provide the correct head of water above the drop nozzle. The constant level reservoir is fed from the bulk reservoir above the clock. When the water drop has completed its function it is collected by surface tension force exerted by the water in the discharge reservoir lower down.

Although the construction appears to be rough it is accurate to one minute per day. It uses about two and a quarter litres of water a day.

More Information

-

Collecting Areas

-

Acquisition Information

Loan & Subsequent Bequest from Captain E. S. Nurse RAN (retired), Aug 1972

-

Maker

Captain Edwin S. Nurse - Royal Australian Navy (RAN), Heathmont, Greater Melbourne, Victoria, Australia, 1968

-

Classification

-

Category

-

Discipline

-

Type of item

-

Keywords