Summary

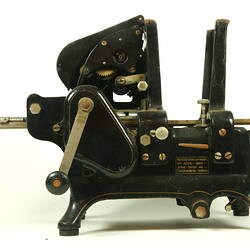

Roneo #40. This is a hand operated device which still works. It includes a box to collect each stencil once it has been used to print an address. To prepare a stencil, the address was typed onto tissue paper. The tissue paper was moistened with a soaking cloth so it would adhere to the cardboard stencil frame. The tissue would be stretched taut on the frame and the metal stencil clamp placed on it. The frame, tissue and clamp would then be placed in a stencil press to secure the stencil to the frame. The address on a stencil is printed when the stencil is run over the inked surface of a rotating cylinder operated by hand. The ink flows through the cuts in the stencil onto an envelope or paper sheet.

This device as well as Roneo # 1makes the Information Technology collection more comprehensive in terms of representative technology. In order to fully represent the historical and the technological developments that have led to modern information technology, the Information Technology Collection encompasses a number of activities and technologies that preceded, run parallel to and/or were absorbed into information technology. Copying and duplicating machines represent a significant development of office machinery that has to a very large extent been absorbed into information technology at least in the 'developed' world. The modern office photocopier is actually a restricted program computer with a specific output.The major types of duplicating machines are: Stencil or mimeograph, Hectograph, Multilith or offset lithograph, Imprinting. Regardless of the process used, all duplicating machines require the preparation of a master copy from which copies are made by a machine. The two Roneo machines are typical examples of hand operated stencil machines. In these machines, the stencil is fastened to the ink-saturated surface of a hollow, rotating cylinder. As the cylinder rotates, ink flows through the cuts in the stencil to the sheets of paper fed under the cylinder. A further reason for acquistion is that their mode of operation can be easilty demonstrated using the comprehensive collection of accessories that the donor provided.

This machine and a Roneo # 1 were used consecutively at the donor's workplace from the 1920s to the 1950s when the firm replaced the #40 with a more modern machine (unknown make). #40 replaced #1 either before, after or during World War II. The firm was the Coleman Quicklite company. The donor took both machines home and used them for addressing envelopes at his local Methodist church until the 1970s. The donor joined the firm in 1932 when he was 15. He was supply manager when he retired in 1975. The box of framed address stencils contains the list of the firm's customers - nothing to do with the church.

The Roneo # 40 uses the same stencils as the # 1. It appears that Roneo ensured compatibility of its accessories for a wide range of machines over thirty odd years.

Physical Description

The Roneo #40 shares these with the Roneo #1 (reg# 45063) * a packet of stencil tissues interleaved with cardboard and transparent sheets (unframed address stencils) * soaking cloth * metal stencil clamps *ink container * stencil press * box of addressed frames

More Information

-

Collecting Areas

-

Acquisition Information

Donation from Mr Norman Nelson, 25 Jul 2001

-

Manufacturer

-

User

-

Classification

-

Category

-

Discipline

-

Type of item

-

Overall Dimensions

62 cm (Length), 25 cm (Width), 25 cm (Height)

-

Keywords