Summary

Alternative Name(s): Steam Truck; Steam Wagon

Restored steam-powered road vehicle with undertype high-pressure twin-cylinder steam engine, vertical cylindrical water-tube boiler, solid rubber tyred wheels and 6-ton capacity 3-way tipper tray. This vehicle was completely rebuilt by steam enthusiasts Peter Adams and Ben Klaster of the Melbourne Steam Traction Engine Club, between 1980 and 1992, using components salvaged by Peter Adams from the remains of several Super Sentinel steam trucks found throughout Australia and New Zealand. The main chassis frame, water tank, water pump, ash pan and cab are replicas of the original parts.

Other principal components used in the restoration are believed to have been sourced from Sentinel Waggon serial no.5638, built by The Sentinel Waggon Works (1920) Ltd, of Shrewsbury, England, in 1924, and imported through William Adams & Co of Melbourne. This truck spent the whole of its working life with Bird Bros Pty Ltd, Fertiliser Manufacturers of Alexandra, New South Wales, being used to collect bones and other animal by-products used in the manufacture of "blood & bone" fertiliser from abattoirs and butchers throughout the Sydney metropolitan area.

The "Super Sentinel" steam waggon design was produced by The Sentinel Waggon Works (1920) Ltd, from 1923 to 1932. It was based on the earlier "Standard Sentinel" steam waggon design that had been in production from 1906 to 1923. At least 100 Sentinel steam waggons were imported into Australia through agents William Adams & Co Pty Ltd of Melbourne and Sydney, including 30-40 "Standard Sentinels" sold from 1921-1924 and about 65 "Super Sentinels" sold from 1923 to 1927. About 15 examples survive today. Most worked in Melbourne or Sydney, although some found their way to other capital cities and parts of regional Victoria and New South Wales. Amongst the key industries in which Sentinel steam waggons were employed in Australia were road construction work, quarrying, fuel merchants, gas works and later saw-milling.

The Museum's steam waggon was bequeathed to the organisation in a partially restored condition by Melbourne steam enthusiast Peter Adams. Adams had always been interested in steam technology and at the age of 15 built his own steam car, based on a 1950s Morris Oxford. His approach was refreshing and somewhat eccentric, for he was reported as saying "Out with that garbage!" as the petrol engine went to the scrap heap to make room for a steam engine. Then, "Out with that junk!" and the passenger seat was gone, making space for a steam boiler. Peter's steam car made its public debut at the Melbourne Traction Engine Club's 1976 Rally at Wantirna and attracted considerable interest. After some time Peter realised another dream by purchasing the remains of a Sentinel steam wagon with three-way tipper body. The vehicle was in a very dilapidated state, with many components worn out or missing. Peter scoured Australian and New Zealand searching for the remains of other Sentinel steam waggons from which he could salvage replacement parts. He spent hundreds of hours devoted to the project and did see the wagon run under steam, although he tragically died before the task could be completed.

Renold Australia provided valuable in-kind support for the restoration of the Sentinel Steam Waggon by providing new drive chains to replace won parts in 1993/94.

Physical Description

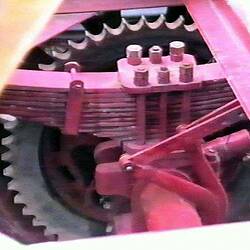

Vehicle Type: 6-ton capacity 3-way tipper steam truck Engine Type: undertype twin-cylinder double-acting poppet-valve Bore x Stroke: 6¾ inch (171 mm) x 9 inch (229 mm) Power-Rating: 90 brake horsepower (68 kW) Boiler Type: vertical centre-flue with spiral water tubes & coil superheater Steam Pressure: 230 psi (1585 kPa) at 650º F (345º C) Fuel: black coal or coke Overall Weight: approx 7 tonnes Maximum Speed: 12 mph (20 km/hour) at 240 rpm (max engine speed)

Significance

Statement of Significance:

The "Sentinel" steam wagon was arguably the most successful British steam vehicle ever designed with almost 8,000 built during a production run of over 40 years. During the first four decades of the 20th century it played a key role in the British road transport industry and to a lesser extent overseas export markets. Its development marked a pivotal point in the transition from steam to internal combustion powered road transport and was crucial in demonstrating the superiority of the undertype steam truck configuration over earlier overtype steam trucks that had evolved directly from the steam traction engines of the late 19th century. Crucial to its success was the advanced enclosed poppet-valve twin cylinder engine and gearbox that protected the main working components from road dust and developed an excellent power-to-weight ratio operating on high-pressure super-heated steam produced by a compact forced-draught-draft water tube boiler that was very responsive to the fluctuating steam demands of a heavily laden vehicle working through varying terrain.

Steam waggons or steam trucks emerged as a distinct class of steam-powered road vehicle in Britain during the late 1890s, following the introduction of the Highways Act of 1896, which eased earlier restrictions on the speed, operating hours and permissible routes that could be used by steam vehicles weighing less than 10 tons.

The original "Sentinel" design (later known as the "Standard Sentinel") was introduced in 1905 by the Glasgow-based marine engineering firm Alley & MacLellan Ltd. Though largely conceived by the firm's managing director, Stephen Alley, the design was influenced by the work of two earlier steam waggon pioneers, Daniel Simpson and W.L. Bodman. The most distinctive aspects of the design were the undertype engine mounted beneath the chassis in the middle of the vehicle, maximising the space available for commercial cargo, the large open chain drive to the rear axle (somewhat akin to an oversize bicycle chain) and the compact vertical boiler with superheater mounted in the middle of the drivers cab, which had excellent steaming characteristics, being quick to get up to temperature and pressure from cold and very responsive to changing steam demand on the road.

By 1915, the Sentinel steam waggon had made such an impact that a separate public company was floated dedicated to its manufacture and a new purpose-built factory was established at Shrewsbury in Shropshire. With the increasing demand for road transport vehicles during the First World War, production of Sentinel steam waggons rose from 300 in 1915 to 600 in 1919 and 900 in 1920, including several large orders for the War Department. The basic Sentinel design, however, had seen little change in almost 15 years. Sales significantly declined during the early 1920s under competition from newer petrol-driven motor trucks.

A updated model, known as the "Super Sentinel" was launched in April 1923, temporarily reviving the company's fortunes. As a sign of the times the Super Sentinel was offered in two basic sizes, with 4-5 ton and 6-7 ton load capacities, and up to 24 different body styles, including a flat tray, tipper tray, enclosed vans, tanker waggon and even a six-wheeled articulated "semi-trailer" version.

The Super Sentinel remained in production until 1932, although a more advanced design with the modern style of rear tail-shaft and enclosed differential drive (the "S-type Sentinel") was introduced in 1927. Production of Sentinel steam trucks continued in a limited capacity at Shrewsbury until 1951. Of the almost 8,000 Sentinels built in total, over three-quarters were built before 1929.

More Information

-

Collection Names

-

Collecting Areas

-

Acquisition Information

Bequest from (Estate of) Mr Peter Anthony Adams, by 1989

-

Manufacturer

Sentinel Waggon Works (1920) Ltd, Shrewsbury, Shropshire, England, Great Britain, circa 1924

-

Restorer

Mr Peter Anthony Adams, Dandenong, Greater Melbourne, Victoria, Australia, circa 1980-1986

-

Restorer

Mr Ben Klaster, Hampton Park, Greater Melbourne, Victoria, Australia, 1989-1992

-

User

Bird Bros Pty Ltd (Bone Merchants & Fertiliser Manufacturers), Sydney, Greater Sydney, New South Wales, Australia, circa 1924-1960

-

Model Name or Number

-

Brand Names

-

Classification

-

Category

-

Discipline

-

Type of item

-

Overall Dimensions

8 m (Length), 2.4 m (Width), 3 m (Height), 6 tonnes (Weight)

Approximate dimensions only.

-

Keywords

Drays & Wagons, Motor Trucks, Sentinel, Steam Road Vehicles, Steam Wagons, Super Sentinel, Tippers