Summary

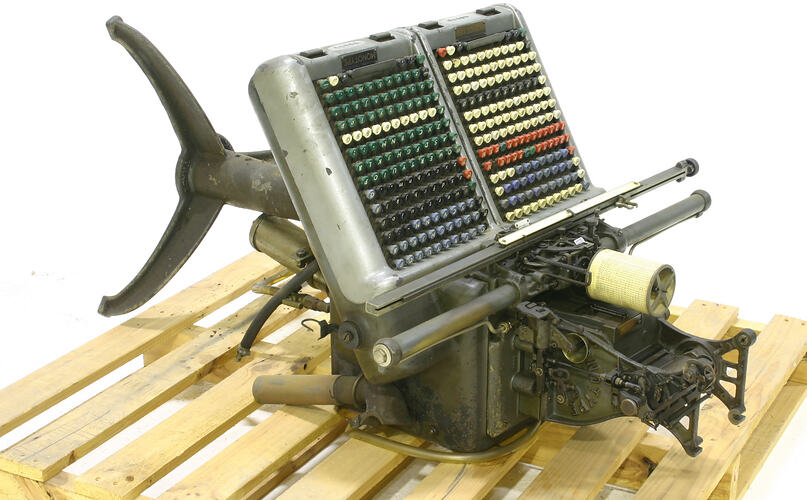

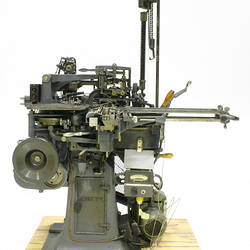

Monotype machine used for typesetting. Made by Monotype Corporation Ltd., London, England.

The Press was presumably bought new by the VGPO.

Operation

The letters on the keyboard are arranged in the same positions as on a normal typewriter, and the copy can be tapped by touch in much the same way. As the operator taps the copy, instructions for the automatic operation of type-casting are recorded by combination of perforations in the paper ribbon that unwinds at the top. Through the "message" on the ribbon, the keyboard tells the Caster what to do. The Caster is a separate machine, the keyboard ribbon being installed for its operation. [See Monotype Composition Caster] Monotype was widely used for book work were it had an advantage over the Linotype in being able to set pages complete, reducing composing time.

Significance

Tolbert Lanston [1844-1913] born in Troy, Ohio, USA, patented a 'type-forming' machine in 1887. Backed by English interests he developed a 'Monotype' machine that was first demonstrated commercially at London in 1897. Because it needed a second machine for casting the type, it was slow to be accepted. Further developed it provided opposition to the Linotype of Mergenthaler and created an industry that continues today (2007). Many type faces were born to feed the Monotype legend and typographical art and design as we know it today is a direct beneficiary of the Monotype machine.

The Press is part of the State's working printing history and representing technological change within the Government Printing Office from hand-set type.

Linotype is the registered trademark of Mergenthaler Linotype Company.

A Linotype machine does not set linotype. It sets a "line of type". The following is out of the Launceston Examiner the day they installed the Model 1.

----------------

Have our readers heard of the "Linotype"? The machine does not set ordinary type, but it casts a whole line of type, hence its name, being an abbreviation of a line of type. It is the invention of Ottman [sic] Mergenthaler, a German watchmaker, of Baltimore, U.S.A., who got the original idea from the typewriter. A fabulously large sum of money has been expended in experiments and subsequent improvements of the machine, until today it may be said to be perfect, the first machine having been erected by the New York Tribune in 1886.

It is operated by means of a key-board, and as the keys are successively touched by the operator's fingers, brass matrices are released and fall in proper order; these, with appropriate spaces for filling out the line, are then passed onto the mould, into which a jet of metal is forced, producing a line of matter ready for printing. Before the line, or "slug" as it is termed, is turned out it is trimmed and made perfectly true. Whilst the operator is engaged with his next line, a long arm reaches down, seizes the matrices that have just left the mould and takes them up and distributes them into their proper channels, to go through the same process over and over again. With the exception of working the keys, the whole process is carried out automatically.

More Information

-

Collecting Areas

-

Acquisition Information

Donation from Victoria: Government Printing Office, Feb 1981

-

Manufacturer

-

Inscriptions

Metal label: Monotype Keyboard 22842 Model Monotype s5e9a. Ser. No. 22842.

-

Classification

-

Category

-

Discipline

-

Type of item

-

Overall Dimensions

60 cm (Length), 90 cm (Width), 125 cm (Height)

-

Keywords