Summary

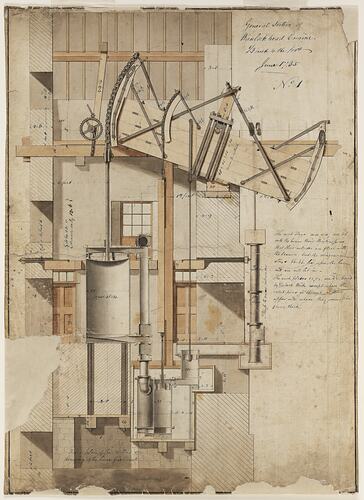

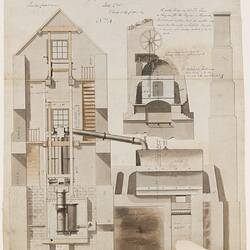

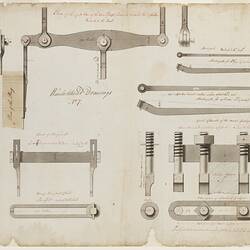

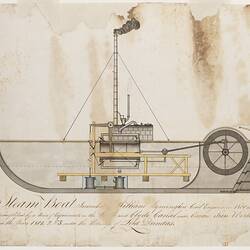

Hand-coloured ink and watercolour drawing showing a general cross-section of an atmospheric condensing beam pumping engine designed by James Watt and supplied by the firm Bolton & Watt, of Birmingham, to the Margaret Mine, at Wanlockhead, Dumfries, Scotland, in 1785-86. Scale: 1/3 inch to 1 foot. The drawing is part of a set of technical drawings supplied by the manufacturers showing general arrangements, details of foundations and key components for a 55-inch (1397 mm) bore x 8 foot (2438 mm) stroke single-acting single-cylinder steam pumping engine ordered for the Margaret Mine by Gilbert Meason, general manager of the Wanlockhead Mining Company, in June 1785. Labelled as sheet No.1, it shows a longitudinal cross-sectional elevation through the three-storey engine house and key components of the engine including the steam cylinder and condenser. The drawing is believed to have been executed by James Watt, or an assistant working under his direction, and includes a number of annotations written in blue ink in what appears to be Watt's hand, giving selected dimensions of the general assembly and other notes to the erectors.

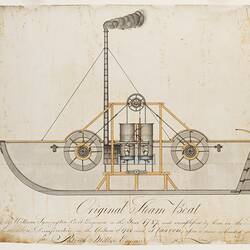

The engine depicted was built to replace a smaller 36-inch (914 mm) bore Boulton & Watt pumping engine erected in 1778-79, which was found to be too underpowered to cope with the drainage load as the mine workings went deeper. At the time that both Watt engines were built for the Wanlockhead mines, Boulton & Watt had not yet established their Soho Foundry (1795), and it was their general practise to just supply drawings for the erection of their engines and organise for the supply of key components from a number of third-party engineering firms across northern England and the midlands. Generally a skilled erector would be sent by Boulton & Watt to supervise installation and commissioning of each engine, but in the case of the Wanlockhead engines, none of Boulton & Watt's regular experts were available, so the work was left in the hands of the mining company's engineer George Symington, assisted by his younger brother, William Symington. The experience would provide one of the most important formative events in the subsequent career of twenty-one year old William, and would help set him on the course of a life-long interest in the applications and improvements of steam technology.

Wanlockhead is a historic mining village situated in the Lowther Hills region of the Scottish Southern Uplands, at the head of the Mennock Pass. It is noted for being Scotland's highest village at an average elevation of 1,531 feet (467 m) above sea level. The area has been exploited since at least Roman times for its mineral resources, which include deposits of lead, zinc, copper, silver and gold. The current village was founded in 1680 when Sir James Stampfield built a lead smelting plant and workers' cottages. Beam pumps powered by a self-acting water bucket were introduced to drain the Wanlockhead mines in 1745. The Wanlockhead Mining Company was formed by Ronald Crawford and associates in 1755, and energetically exploited the area's rich lead veins over the following sixty years, working deposits to depths of over 540 feet (165 m), and producing 47,420 tons of lead. They were the first Scottish mine owners outside the Edinburgh coalfields to adopt seam powered pumping technology.

William Symington appears to have kept several of the original Wanlockhead Steam Engine drawings as a memento of his involvement and would later pass them onto his second-oldest son, William Symington junior (c.1802-1867), who bought the surviving drawings to Australia when he emigrated in 1855. They were subsequently donated to Museum Victoria by a descendant of the family.

Description of Content

WANLOCKHEAD ENGINE DRAWING NO. 1 BY JAMES WATT. JUNE 1785. FURTHER DOCUMENTATION REQUIRED. TO BE NUMBERED.

Physical Description

Scaled (1/3 inch to 1 foot), hand-coloured (brown, grey, black) technical line drawing annotated with handwritten text and dimensional details in blue ink. The drawing shows a sectional view of an engine house and atmospheric beam engine with cutaway sections of the foundations and mounting bolts.

More Information

-

Collecting Areas

-

Acquisition Information

Cultural Gifts Donation from Dr Graeme R. Symington, by 03 Feb 1993

-

Creator (Attributed)

Mr James Watt, Birmingham, Staffordshire, England, Great Britain, 1785

-

Manufacturer of Item Depicted

Boulton & Watt, Birmingham, Staffordshire, England, Great Britain, circa 1785-1787

-

Place Named

-

Past Owner or User

Mr William Symington Snr, C.E., Scotland, Great Britain, circa 1785-1831

-

Past Owner

Mr William Symington Jnr, C.E., Bacchus Marsh, Victoria, Australia, circa 1855-1867

-

Past Owner

Miss Nancy M. Symington, Bacchus Marsh, Victoria, Australia

Great-granddaughter of William Symington, snr. She owned the drawings prior to passing them on to the donor. -

Individuals Identified

WATT, JAMES

-

Format

Drawing

-

Inscriptions

Title, top right corner, handwritten: 'General Section of / Wanlockhead Engine / 1/3 inch to the foot / June 1785 / No. 1' Watermark: 'J Whatman' Note, middle, right side, handwritten: 'The arch stays aa aa are let / into the beam their thickness so / that their outsides are flush with / the beams - but the diagonal / stays bb bb be upon the beam / and are not let in. / The arch plates cc, cc, are 3 1/2 in broad / by 5/8 inch thick except where the / catch pins go through at their / upper end where they must be / 1 inch thick.', 'Pump to raise hot water', 'beam 2 inches thick' Note, bottom, left corner, handwritten: 'For a plan of the cellar see / drawing of the house first sent.'

-

Brand Names

-

Classification

Mechanical engineering, Steam power, Diagrams - beam steam engines

-

Category

-

Discipline

-

Type of item

-

Overall Dimensions

320 mm (Width), 447 mm (Height)

-

References

[Book] Harvey, W.S. & Downs-Rose, G. 1980. William Symington - Inventor and Engine Builder., See plate 6, p.17. Pages

-

Keywords

Atmospheric (Steam) Engines, Beam Engines, Engineers, Engines, Innovation & Design, Inventions, Lead Mining, Mining Equipment, Patents, Pumping Engines, Steam Engines