Summary

At Kodak Australasia Pty Ltd, maintenance of the manufacturing plant and equipment was crucial to efficient operations. Kodak's team of tradesmen were responsible for constructing new equipment as well as keeping the plant in good working order.

At Kodak Australasia Pty Ltd, maintenance of the manufacturing plant and equipment was crucial to efficient operations. Kodak's team of tradesmen were responsible for constructing new equipment as well as keeping the plant in good working order.

Thomas Baker began making glass photographic plates in 1884 at Abbotsford. His business grew and evolved, becoming Kodak (Australasia) Pty Ltd in 1920 (Beale p.17). As the plant expanded to include machinery for making roll film and photographic papers, plus a range of other photographic products, the complexity of the operations increased. So did the need for increased technical support. Baker, who died in 1928, left a legacy of self-sufficiency, by setting up workshops and employing tradesmen of every kind to maintain and build the equipment used in the factory (Beale p. 21).

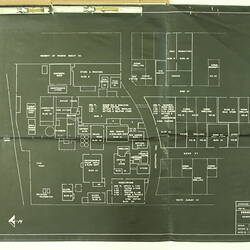

The Abbotsford workshops comprised a carpenters shop with a timber store and breaking down shed, a sheet metal shop, engineers shop, and workshops for pipe fitters and plumbers, painters and electricians.

Jim Healy, who joined Kodak as a maintenance engineer in 1951, was one of a dozen metal workers who looked after Kodak's manufacturing machinery in the mid twentieth century. Part of Jim's job involved maintaining the pumps and other components of the machine used for coating rolls of paper and base material with photographic emulsions. Tradesmen needed to be on hand in case of a breakdown, which, Jim recalls, were not very frequent because the machines were well maintained. Every year the manufacturing plant shut down for two weeks, when most employees took their Christmas holidays. During shut-down the workshops' tradesmen completely overhauled the manufacturing plant, ready for the start of another busy year.

Besides maintaining the factory, the workshops' tradesmen also worked with Kodak's engineers to construct some of the specialised machinery Kodak used. Jim Healy worked on the construction of a machine for slitting the large rolls of film and photographic paper into long strips. There was also an experimental workshop. Jim remembers assisting the engineering draftsmen:

If they'd get an idea to do something, we'd try to make it up to see if it would work before it had been actually manufactured in the machine shop for production use. We made this little coating machine. If they wanted to try a new type of emulsion or test it out instead of going straight into production, we used to run it on this little coating machine.

Sometimes the workshops, with the approval of management, made small items such as letterboxes for employees. These items were known as 'foreigners'. Jim remembers:

You'd sort of start a bit early or cut out your morning tea and do a few things. Of course there was a lot of scrap metal around too, otherwise they used to get rid of it. In the carpenter's shop they'd get a bit of timber out and they'd make a stool and things like that for you. They'd give the apprentices a few of these jobs, away from the standard things.

Kodak's engineers and tradesmen at Abbotsford were in high demand from the late 1950s when they designed and built some of the new plant installed at the new Coburg complex, which opened in 1961 (Healy, Beale pp 117, 121). The Abbotsford tradesmen transferred to new modern workshops at Coburg, where they continued their tradition of providing a high standard of maintenance.

References:

Beale, Nigel, "The History of Kodak in Australia", 1983.

Oral History:

Jim Healy, interviewed by Lesley Alves at Melbourne Museum, 12 March 2014.

More Information

-

Keywords

-

Localities

-

Authors

-

Article types