Summary

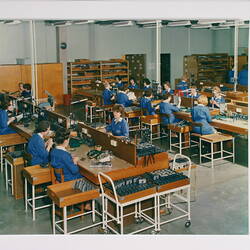

Colour photograph featuring assembly line operations in the Camera Section for the production of the Instamatic range of cameras. The cameras were assembled in the Cameras, Reels and Sundries Department, Building 15, at the Kodak factory complex in Coburg, circa 1963.

Staff included:

On table at left. On left side, from front, unknown, Ann, Maureen ?, Carmel.

On table at right. On right side, unknown, Marilyn, Herta ?, unknown, Evelyn, Barbara.

The camera section commenced operations in 1957 at Abbotsford with the production of the Brownie Flash II Camera. Operations moved to Coburg in 1961 and in 1963 production of the Instamatic range began. In the years to 1965 camera production progressed rapidly through a range of cameras to a daily output of over a thousand of the Instamatic range. Camera production ceased in 1981 when intense competition from Asian manufacturers made the operation unviable.

The type of production line assembly used required a steady flow of accurate parts to the assembly line whether they were imported or made in-house. With the numbers and complexity of parts involved, even in a simple camera, extremely close control of parts ordering, specification checking, quality and delivery scheduling were essential.

The Reels & Sundries Section of this department produced a large range of products, from roll-film spools, movie reels, 135 magazines, 126 cartridges, super-8 cartridges, aero spools, compartment file boxes, X-ray hangers, silver recovery units to slide-film readymounts. Parts produced for local camera assembly were mainly from metal stamping and forming operations but with the advent of the Instamatic range the work load shifted towards plastic injection moulding. Both metal and plastic parts production required accurate machinery and tooling and the qualified engineering staff needed to support them including engineers, toolmakers and fitters.

Accurate quality control, production control and stock control were essential in the Cameras, Reels & Sundries Department as over 100 different products ranging from production rates of eventually over 80 million a year down to 50 per year were required. Many of these items required special quality control equipment and very intricate tooling to give the quality and speed of production required. An example of this was the gauges used to check the flatness of the film pads in 126 cartridges used in the Instamatic camera range.

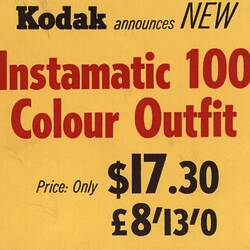

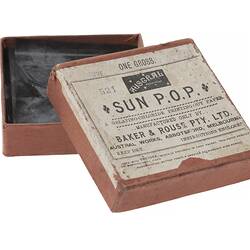

Kodak manufactured and distributed a wide range of photographic products to Australasia, such as film, paper, chemicals, cameras and miscellaneous equipment. Its client base included amateur and professional photographers, as well as specialist medical and graphic art professionals who used photography, x-ray and other imaging techniques.

This photograph is part of the Kodak collection of products, promotional materials, photographs and working life artefacts collected from Kodak Australasia in 2005, when the Melbourne manufacturing plant at Coburg closed down.

Description of Content

Photograph features a view of assembly lines of staff producing cameras. The women are seated in rows at workstations assembling various parts and stages of a complete camera range. Each woman has containers with raw, part-assembled or fully-assembled parts either side of the workstation representing the input and output of the individual's work.

Physical Description

Colour photograph printed on medium weight paper, landscape format.

More Information

-

Collection Names

-

Collecting Areas

-

Acquisition Information

Donation from Kodak (Australasia) Pty Ltd, Ms. Kate Metcalf - Kodak (Australasia) Pty Ltd, 2005

-

Acknowledgement

Courtesy of Kodak (Australasia) Pty Ltd.

-

Place & Date Depicted

Coburg, Greater Melbourne, Victoria, Australia, 1963

Instamatics started being made at the Coburg factory in 1963. Ritter-Jeppesen took photographs probably January 1963. -

Organisation Depicted

Kodak (Australasia) Pty Ltd, Elizabeth Street, Coburg, Greater Melbourne, Victoria, Australia, 1963

Instamatics started being made at the Coburg factory in 1963. Ritter-Jeppesen took photographs probably January 1963. -

Photographer

Ritter-Jeppesen Studios Pty Ltd, Coburg, Greater Melbourne, Victoria, Australia, 1963

Ritter-Jeppesen probably took these photographs January 1963. -

Format

Photograph, Colour

-

Classification

-

Category

-

Discipline

-

Type of item

-

Image Dimensions - Photograph

239 mm (Width), 190 mm (Height)

-

Keywords

Factories, Manufacturing, Photography, Cameras, Assembly Lines, Photographic Products