Summary

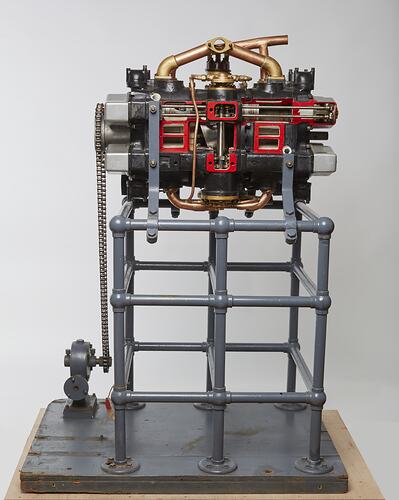

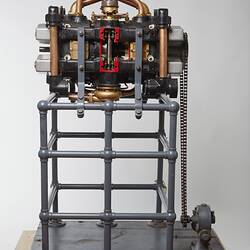

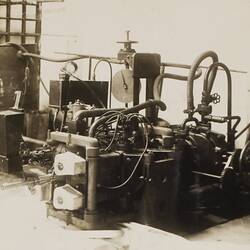

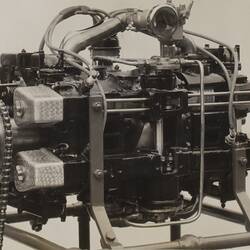

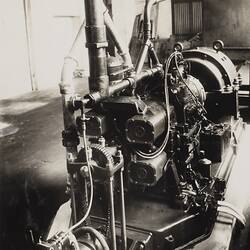

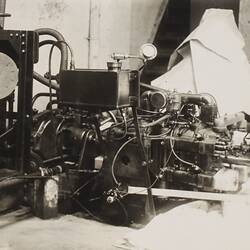

Prototype crankless automotive engine built by Crankless Engines (Aust) Pty Ltd, of Greeves Street, Fitzroy, Victoria, in 1923, allocated as Machine No.12. The design was based on the principles outlined in Anthony George Maldon Michell's Australian Patent No.4627, for "Improvements in Mechanism for the Interconversion of Reciprocating and Rotary Motion", with detailed design work undertaken by a small team of draughtsmen employed by Crankless Engines under the supervision of Thomas Louis Sherman, an experienced automotive engineer, who worked as Michell's senior design collaborator from 1920.

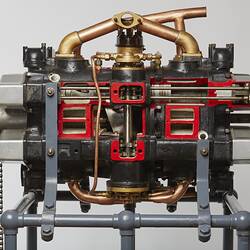

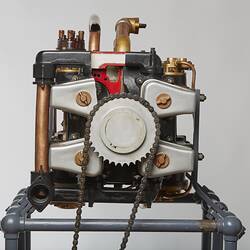

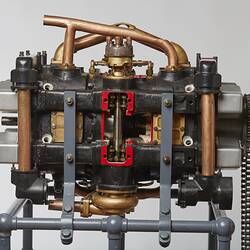

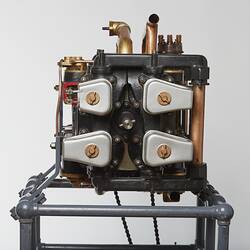

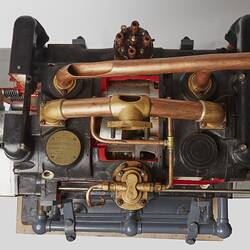

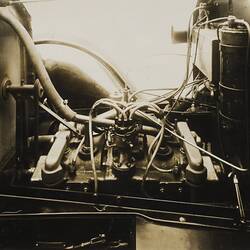

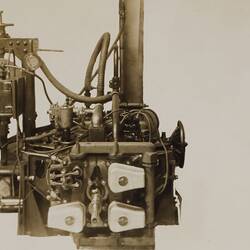

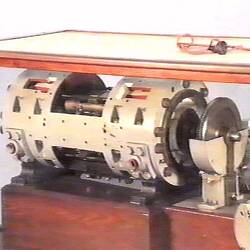

The 8-cylinder naturally aspirated spark-ignition petrol engine is of a is double-ended configuration utilising a tilted swash plate (referred to by the inventor as a 'slant'), in place of a conventional crankshaft to transfer the reciprocating motion of the pistons into a revolving central drive shaft. The single-acting pistons are arranged in four pairs forward and aft of the swash plate, with each pair rigidly connected by a central cast steel yoke straddling the swash plate. Each yoke incorporates two opposing hemispherical bronze cups into which are fitted slipper pads with a hemispherical boss on the back face and Babbitt white metal bearing surface on the side facing the slant. As the slant rotates, the slippers tilt slightly creating a wedge-shaped film of lubricating oil between the sliding surfaces minimising friction, similar to the principle of the tilting pads in Michell's original thrust bearing invention of 1905.

The engine has conventional tappet, pushrod and rocker type valve gear, two gear type oil pumps, and a single Zenith No.36 triple diffuser carburettor with custom inlet manifold. With a capacity of just under 4 litres, and a compression ratio of 5:1, it delivered 35 BHP at 1250 r.p.m. and 60 BHP at 3000 r.p.m. on the test bed. Overall dimensions were approximately 28 inches (710 mm) in length x 15 inches (380 mm) wide x 20 inches (508 mm) high, with an overall weight of about 500 lbs (230 kg), of which the 2.06 inches (52.3 mm) thick x 10 inches (254 mm) diameter forged steel slant weighed 40 lbs (18.2 kg).

After extensive dynamometer testing at the works of Crankless Engines (Aust) Pty Ltd, the engine was taken to Britain by Major Richard G. Casey (later Lord Casey), a director of the company and close associate of Michell, for demonstration to automotive companies. Extensive independent testing by Sizaire Berwick Ltd, at Park Royal, London, confirmed the earlier performance and provided a favourable comparison to a standard 6-cylinder 4.6 litre Buick engine, with results published in an article appearing in the British journal 'Engineering' of 5th Oct 1923.

Subsequently the engine was taken to the United States, where it underwent assessment at both the General Motors research establishment in Dayton, Ohio and at the Ford Motor Co. in Detroit, Michigan, and was demonstrated to other automotive components manufacturers. Despite the initial Interest, manufacturing licences failed to eventuate, in part due to the perceived costs that would have been involved in retooling existing manufacturing plants to produce the entirely new type of engine. Later the engine came into the possession of Steel Products Engineering Co. (Speco), a supplier of automotive components based in Springfield, Ohio, with whom T.L. Sherman had a long association, working as a consultant on the development of Michell crankless aero engine designs, and later as an employee from 1943. After some years on display in the Speco works museum, the engine was generously donated to the Science Museum of Victoria in March 1976 by the Speco Division of Kelsey-Hayes Company, Ohio, and was transported back to Melbourne on behalf of the museum by the RAAF. The engine was restored by Super Spread Aviation Australia Pty. Ltd., Cheltenham, Victoria, in January 1977, prior to going on display.

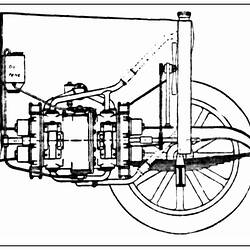

A second crankless automotive engine of the same design, Machine No.14, was also built by Crankless Engines (Aust) Pty Ltd, and subsequently fitted to the chassis of a Buick Master Six 4-Door Touring Car. During Easter 1924, T.L. Sherman, drove the car to Sydney and back over a 1,423 mile (2,290 km) 8-day road trip, returning by the coast road, accompanied by Vic Wilson and Norman Matthews, a mechanic with the firm. The crankless engine performed admirably, without incident, despite the arduous road conditions and heavy rain encountered on the return trip.

Physical Description

Specifications: Number of Cylinders: 8; Bore: 3.312 inches (84.12 mm); Stroke: 3.51 inches (89.15 mm); Capacity: 3.96 litres; Compression Ratio: 5:1; Power Output: 35 BHP (26 kW) at 1250 r.p.m.; 60 BHP (44.7 kW) at 3000 r.p.m.

More Information

-

Collection Names

A.G.M. Michell Engineering Collection, Crankless Engines Collection

-

Collecting Areas

-

Acquisition Information

Donation from Speco Division, Kelsey-Hayes Co., Mar 1976

-

Manufacturer

Crankless Engines (Australia) Pty Ltd, 129 Greeves Street, Fitzroy, Greater Melbourne, Victoria, Australia, circa 1923

Crankless Engines (Aust.) Pty Ltd was registered as a private company on 24th August 1920, with a capital of £6,000 in £1 shares. The firm converted to a public company Crankless Engines Ltd. in 1924. -

Inventor

Mr Anthony G. Michell, Melbourne, Greater Melbourne, Victoria, Australia, 1917

The design was based on A.G.M. Michell's Aust. Pat. No.4627, for "Improvements in Mechanism for the Interconversion of Reciprocating and Rotary Motion". -

Designer

Mr Thomas L. Sherman - Crankles Engines (Aust.) Pty Ltd, Melbourne, Victoria, Australia, circa 1923

T.L. Sherman worked closely with A.G.M. Michell on the detailed design of the early machines made by Crankless Engines (Aust.) Pty Ltd. Under the title Chief Engineer, he was initially responsible for managing both the firm's design design office and workshop. -

Past Owner

Speco Division, Kelsey-Hayes Co., Springfield, Ohio, United States of America, circa 1940s-1976

The engine was owned by Kelsey-Hayes Co. prior to being acquired by the Science Museum of Victoria in 1976 and was on display in the showroom/foyer of their Speco Division headquarters in Springfield, Ohio. -

Restorer

Super Spread Aviation Australia Pty Ltd, Cheltenham, Greater Melbourne, Victoria, Australia, Jan 1977

The engine was restored for the museum by Super Spread Aviation Australia Pty Ltd prior to first going on display in Melbourne. -

Inscriptions

Manufacturer's Plate: 'DESIGNED / --- AND --- / MANUFACTURED / ---- BY ---- / CRANKLESS ENGINES LTD. / MELBOURNE. VICTORIA. AUST. / MACHINE No.12 / No. OF CYL. 8 BORE 3.312 STROKE 3.51 / PATENTS / AUSTRALIA 4627/17. / GT. BRITAIN 118098 / FRANCE 490768'

-

Brand Names

-

Classification

-

Category

-

Discipline

-

Type of item

-

Dimensions

230 kg (Weight)

-

References

Refer to SMV Annual Report, 1974-75, p.6.

[Article] Kendall, F.J. (John). 2001. A Listener's Reward: The Michell Crankless Engine, in Rasmussen, Carolyn. 2001. A Museum for the People: A History of Museum Victoria and its predecesors, 1854-2000. pp.181-182., 2001, pp.181-182 Pages

[Article] Cherry, T. M. 1962. Anthony George Maldon Mitchell, 1870-1959. Bio Memoirs of Royal Soc. No.8, 1962, pp.90-103 Pages

[Manuscript] Walker, Sydney E. Modest Man of Genius: An Account of Anthony Geroge Maldon Michell and The Crankless Engine., 1972 [updated Oct 1976]

[Book] Phillip, Stephen. 2020. What Came out of the Box: A Biography of AGM Michell.

-

Keywords

Automotive Engineering, Industrial Design, Innovation & Design, Internal Combustion Engines, Inventions, Mechanical Engineering, Motor Car Engines, Motor Cars, Petrol Engines