Summary

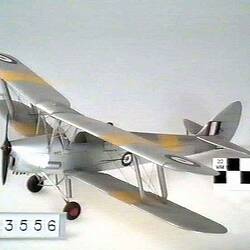

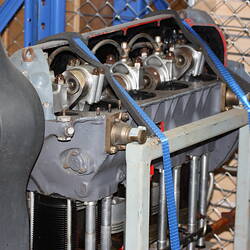

The Gipsy Major was designed and built by the De Havilland Aircraft Co. as a development of the Airdisco Cirrus four-cylinder, air-cooled aero engine. The Cirrus utilised First World War surplus engine components such as cylinders and pistons from RAF 1A and Renault V8 engines. De Havilland produced the Gipsy I, II & III engine which was fitted to the DH 60 Gipsy Moth biplane from 1927. De Havilland's Frank Halford redesigned this engine as the Gipsy Major which inverted the design to put the four cylinders facing downwards to provide the clean single piece upper cowling used on the DH 82 Tiger Moth which appeared in 1932. This design was also adopted for the Gipsy Six engines used on such aircraft as the three DH 88 Comet aircraft which competed in the 1934 England to Australia Centenary Air Race.

Australian production of the 130 horsepower Gipsy Major Series I engine was planned in 1939 following the start of World War II and the rapid expansion of pilot training required for the Empire Air Training Scheme. De Havilland Australia was producing the DH 82A Tiger Moth trainer at Mascot in Sydney and supply of engines from overseas could not be guaranteed. General-Motors-Holden Ltd were the lead contractor for the Gipsy Major program but problems emerged when the drawings supplied were found to lack details required for production and even worse, were apparently intended for French use as the measurements were in metric units which required the conversion of thousands of dimensions to imperial units then in use. De Havillands sent two engineers and two engines to Australia to assist with the project. About 85 different sub-contractors made parts for the Gipsy Major and each received drawings and the appropriate component from one of the two imported engines which had been dismantled for this purpose. Twenty sets of parts were built for testing and of these sets, two were selected as the proof samples, one full set was kept by GM-H and the other approved component returned to the sub-contractor as a proof sample for that part. GM-H assembled and tested completed engines at Fishermans Bend, Melbourne. This was the first engine of any type produced by GM-H. The first locally built engine (serial no. T.1) was tested by the CSIR Division of Aeronautics (ARL) in May 1941. About 1300 Gipsy Major engines were built in Australia as one of the more extensive wartime production projects. The Series II engine had an increase in power output to 140 horsepower.

The Museum's Gipsy Major Series II engine (serial no. 9038) was built by the De Havilland Engine Co Ltd in the United Kingdom and delivered to Australia in September 1939. In late September 1939 it was issued to de Havilland Australia and fitted to Tiger Moth A17-17 during production in Sydney. The fuselage for this aircraft had also been built in the UK. Tiger Moth A17-17 served with No. 2 Elementary Flying Training School based at Archerfield in Queensland. Engine no. 9038 was removed from A17-17 in May 1941, receiving a complete (180 hour engine time) overhaul at Aircrafts Pty Ltd, Archerfield and was later fitted to Tiger Moth A17-16. The engine was transferred to the Museum by the RAAF in 1946. It later sectioned for display purposes.

More Information

-

Collecting Areas

-

Acquisition Information

Donation from Royal Australian Air Force (RAAF), 1946

-

Manufacturer

-

User

Royal Australian Air Force (RAAF), Melbourne, Greater Melbourne, Victoria, Australia

-

Brand Names

-

Classification

Air transport, Aero engines, Reciprocating propeller engines

-

Category

-

Discipline

-

Type of item

-

Overall Dimensions

1350 mm (Length), 915 mm (Width), 2130 mm (Height)

-

Dimensions

135 cm (Length), 91 cm (Width), 213 cm (Height)

Measurement From Conservation. Measuring Method: maximum dimensions

-

Dimensions

890 (Length), 884 (Width), 245 (Height)

Measurement From Conservation.

-

Keywords

Aero Engines, Internal Combustion Engines, Military Aircraft, Wars & Conflicts, World War I, 1914-1918, Centennial Air Race, London to Melbourne, 1934