Summary

From 'roll room boy' to production planner, 1955-1991.

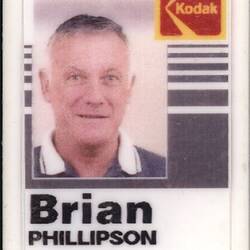

Brian Phillipson, Kodak Australasia Pty Ltd: Paper Coater, Storeman, Safe Lighting Serviceman, Planner, 1955 - 1991

Brian Phillipson left school at 13 and worked for five years doing advertising lay-outs for a furniture company, before he commenced working at Kodak in 1955. He remained at Kodak for 36 years, performing a variety of jobs, including twenty-two years as a safe lighting serviceman. He had no formal qualifications; all his skills were learnt on the job.

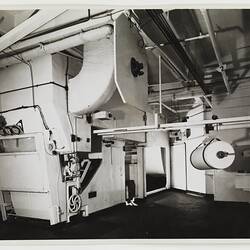

Paper coater

Kodak Australasia's main activity was manufacturing photographic products by coating paper or film base with light-sensitive emulsions. Brian's introduction to the coating process was at Kodak's Abbotsford factory where he was a 'roll room boy'. His job was to move large rolls of coated photographic paper from the coating machine to the store. After six months, Brian progressed to the job of paper coater, operating the coating machine for black and white photographic paper at first. He ran the first coating of colour print paper in the late 1950s.

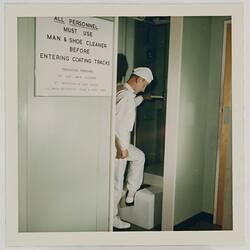

The coating room was a darkened environment, because exposure to light would damage the photographic products being made. After a few years, Brian tired of working in the dark and asked for a change.

Storeman

Brian became a storeman, looking after the supply of paper rolls for the coating machine at Abbotsford. When Kodak moved to a new factory at Coburg in the early 1960s, Brian moved to the store that held the film base and paper for the whole range of photographic products Kodak made, including film for x-ray and graphic arts, as well as roll film and paper for professional and amateur photographers. He was responsible for the movement of stock in and out of the store and for stock control. In the mid 1960s he had another change, becoming a safe lighting serviceman.

Safe lighting

The role of the safe lighting serviceman was to provide suitable low intensity lighting to ensure the photographic product being made was not exposed to any damaging light, while maintaining a safe and practical environment for employees working in the dark. It was an interesting job and Brian believes that he and his boss, Reg Gunson, were the only two safe-lighting experts in Australia at the time. Together they developed the plans for safe lighting in all the darkened manufacturing, processing and storage areas at Kodak's new Coburg plant. They worked with electricians and electrical engineers to make lights of the colours and intensities appropriate for each work site or store. They also experimented to determine how long products could be exposed safely to light.

Brian's expertise was based on an understanding of the colour spectrum, but he developed the practical application of safe lighting through trial and error, as he observed:

'I'm not a tradesman, I'd come from a labourer at Abbotsford. I've got no certificates or diplomas or anything like that, it's all self applied.'

Brian and Reg wrote a manual for each room, stipulating the type and colour of safe lights required. Brian's job included replacing the light globes when necessary. He remembers:

'If we had to change a globe we could go up in the white light up in the ceiling area - most of the ceilings at Kodak you could stand up in - you'd go along and you'd feel the beehive, and if it never had any warmth in it you'd know the globe was gone. So you'd carefully unscrew that - and the head wouldn't come out so you wouldn't let any white light through to the coating room - change the globe, and screw the housing back on. People used to think we were just globe jockeys - no way. We were there because it had to have the right globe.'

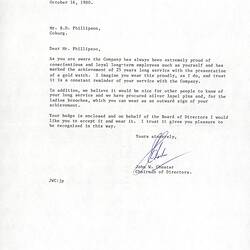

In 1980 Brian celebrated 25 years employment at Kodak. This was, according to Kodak tradition, marked with the presentation of a silver lapel pin, a gold watch and an invitation to the annual dinner dance for all those who attained the 25 year milestone. As Brian comments:

'Whether you're the cleaner, or you're the director, you get the same gold watch. So I appreciate Kodak for that because there's no demarcation, they're doing the right thing by everybody.'

At the Coburg plant Kodak provided a staff recreation and health facility called the Fit Pit. Employees could work out at the Fit Pit gymnasium and have their health monitored by the staff doctor. Brian, a keen sportsman, took advantage of this service. In the monitoring process high blood pressure was detected. Brian was also beginning to experience disorientation when climbing ladders to change the light bulbs, so it was time for a change from his safe lighting job.

Production planner

His new position in the mid 1980s was a production planner in Field Group 1. For this Brian was required to learn some computer skills, which he gained through on the job training. The group ran emulsion making and coating and was located in buildings 2 and 3. Brian kept the records of the hours worked and materials used. When Field Group 1 increased productivity by 6% each member of the group received a commemorative pen recognising their efforts. Brian still has his pen.

Ending a Kodak career

In 1991 Kodak was offering generous redundancy packages, and Brian, at the age of 55, decided to accept one. He subsequently worked part-time as a cleaner for a few years.

References

Beale, Nigel, 'The History of Kodak in Australia', 1983 (unpublished manuscript).

HT 35730 - Interview with Brian Phillipson, interviewed by Lesley Alves 12 December 2013.

More Information

-

Keywords

Manufacturing, Photographic Products, Biographies, Managers, Marketing

-

Localities

-

Authors

-

Article types