Bluestone is a popular name given to several different types of stone, coined to distinguish it from other more greyish basalts. Victorian bluestone is a basalt or olivine basalt, quarried from the vast basalt layer that covers Victoria from Melbourne in the east, to Portland in the west, and as far north as the Great Dividing Range. Deep outcrops of this rich basalt layer were first quarried in the 1830s and 1840s, in the Fitzroy Gardens, Carlton and Clifton Hill, guaranteeing an abundant supply of bluestone for Melbourne's early buildings. During the second half of the 19th century, bluestone quarrying spread west and north, with quarries opening in Williamstown, Footscray and Brunswick; and later Coburg and Preston.

The rapid expansion of the city of Melbourne after the discovery of gold required readily available sources of suitable building stones. Basalt was plentiful, relatively easy to work with and stronger than many other materials available at the time. Large amounts of the stone quarried in Melbourne were used to provide ballast for returning ships; however bluestone was predominately used for many of Melbourne's major buildings, warehouses, building foundations, walls and bridges. Bluestone became popular for use in laneways, curbing and channelling, with bluestone 'pitches' used to duplicate the cobbles of English streets. Bricks gradually came to replace stone as the preferred building material.

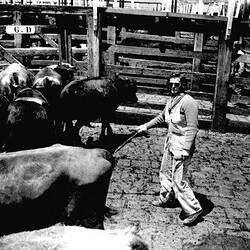

Bluestone pitches at Newmarket Saleyards were laid using masons hammer and bolster chisel by a basic technique involving setting large stones with their long axis into the ground, packed tight together and wedged with smaller stones as necessary. The Newmarket Saleyard pitches were laid in indented patterns to provide automatic drainage and direct effluent; to prevent the workers from slipping; and to stop the cattle from 'bunching' and give them a better surface for their hooves to grip. Also notable at the Newmarket Saleyards are the single bluestone 'gate stops' which were located in the gateway to many pens.

The City of Melbourne was responsible for maintaining the Newmarket pavements. The bluestone pitches were positioned using thumpers - large and solid pieces of wood used to 'thump' the bluestone into a sand base. There are three examples of these thumpers in the Newmarket Collection.

When the Newmarket Saleyards were dismantled, much of the bluestone was recycled. It is estimated that there were 1.6 million bluestone paving stones at the Saleyards. Some 480,000 of these went to council depots, another 480,000 for reuse on the project site and the remaining 700,000 were sold to the public at $2.50 each.

References:

Footscray Institute of Technology Humanities Dept. 1984, 'The industrial archaeology of the Newmarket saleyards and meatworks complex, Victoria : a report / compiled by engineering students in the course HU 151 (Work, Technology and the West) during ...1984', rev. Ed. Footscray Institute of Technology Humanities Dept., Footscray.

Vincent, K. 1992, On the fall of the hammer : a personal history of Newmarket saleyards, Lee White ed, State Library of Victoria, Melbourne.

Vines, G. 1993, Quarry and stone: bluestone quarrying, stonemasonry and building in Melbourne's west, Melbourne's Living Museum of the West, Melbourne.

http://www.emelbourne.net.au/biogs/EM01213b.htm

http://home.vicnet.net.au/~flemweb/localhistory_newmarket.html

More Information

-

Keywords

-

Authors

-

Article types