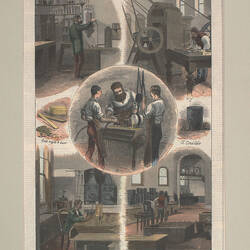

It is necessary that coins of each denomination are identical. To achieve this, the working dies from which the coins are made must be identical. However these working dies have a relatively short life, so additional steps are necessary in die production. There are master dies and hubs. A master die looks like a working die but is only used to make steel hubs. Hubs look like the coins but are only used to make working dies.

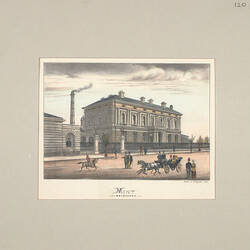

By 1923 the workforce at the Melbourne Mint had developed most of the skills in die production that had seen them earlier reliant on London. It was decided that they would move to the next stage and develop their own master dies.

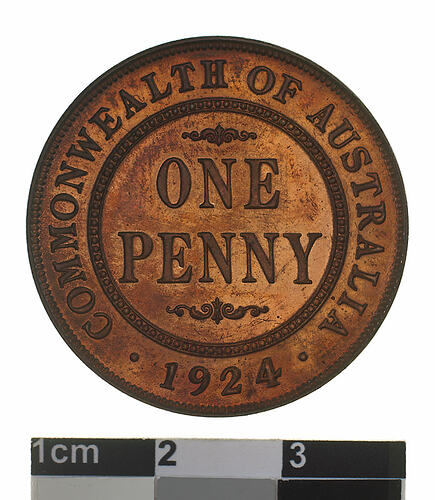

In 1923 the technicians at the Melbourne Mint took one of the hubs and filed off the last numeral of the date (it was raised as on a coin). They then used this hub to make a master die with no final number in the date and using a punch borrowed from a local Melbourne medal producing firm, Stokes and Sons, entered the last number of the next year's date. This die was hardened and tested with success.

At that point an order was sent to London for sets of numeral punches identical to the numerals used on the coinage and sets of master dies and hubs for all silver denominations were prepared. So proud of this work was the mint that it made specially polished dies, called proof dies, and struck a small number of proof sets. Two of these sets were sent to a major exhibition of the products of the British Empire being held in London in 1924.

Reference

Sharples, J.P. "Australian Penny Master Dies of George V", Journal of the Numismatic Association of Australia, Vol.6, pp. 21-29.

More Information

-

Keywords

-

Authors

-

Article types