Summary

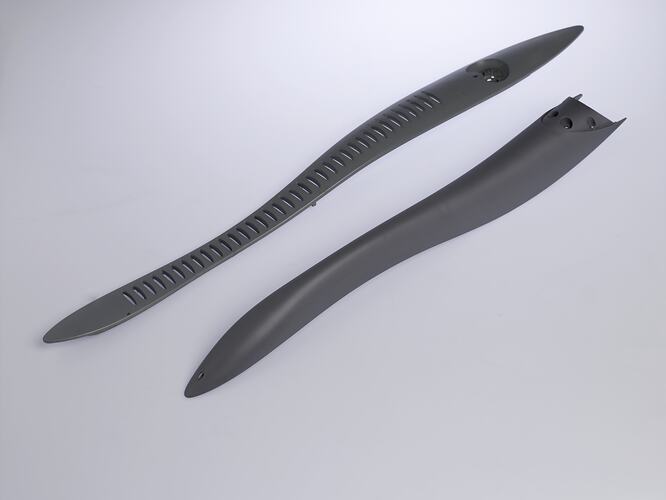

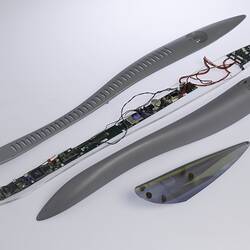

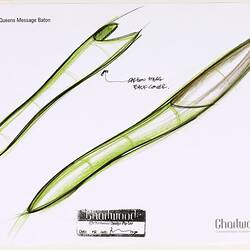

Front Panel prototype of the Queen's Baton made for Charlwood Design, as part of the development of their design for the Melbourne 2006 Queen's Baton. Front and rear prototype baton panels were 'grown' from plastic resin using stereo lithographic printing. In this process, a laser binds 0.1mm thick layers of plastic together to create a three-dimensional form. This process is commonly used to prototype new products. First a Computer Aided Design drawing is created. Then this data is used to program the Stereo Lithography Apparatus (SLA) in which the object is then 'grown'.

International prototyping company ARRK Silhouette's Melbourne facility at Hawthorn produced these prototypes, which exactly match the finished Baton. Charlwood design assembled a prototype baton from these parts, with a prototype circuit board. This front panel was cracked during testing, and was welded back together by Charlwood Design.

Physical Description

Grey plastic to scale prototype of the Melbourne 2006 Queen's Baton. Long and curved towards the middle, vent holes run the length of the model. A recessed circle at one end has holes for screws.

More Information

-

Collection Names

-

Collecting Areas

-

Acquisition Information

Donation from Charlwood Design Pty Ltd, Mr Paul Charlwood - Charlwood Design, Mar 2006

-

Designer

Charlwood Design Pty Ltd, 522 Flinders Lane, Melbourne, Victoria, Australia, circa 2005

-

Manufacturer

-

Classification

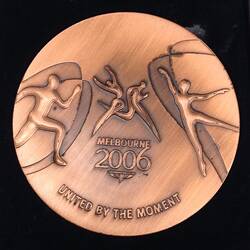

Public events, Commonwealth games - melbourne 2006, Ceremonial objects

-

Category

-

Discipline

-

Type of item

-

Overall Dimensions

91 cm (Length), 8 cm (Width), 4.7 cm (Height)

-

Keywords

Commonwealth Games: Melbourne, 2006, Sport, Theatre, Theatrical Designs