Summary

Steve Brain was expected to work in his family's orchard, but decided he preferred city life. In 1958 he accepted a job at Kodak Australasia as a film tester at the Abbotsford plant. This is the story of his career in quality control and testing.

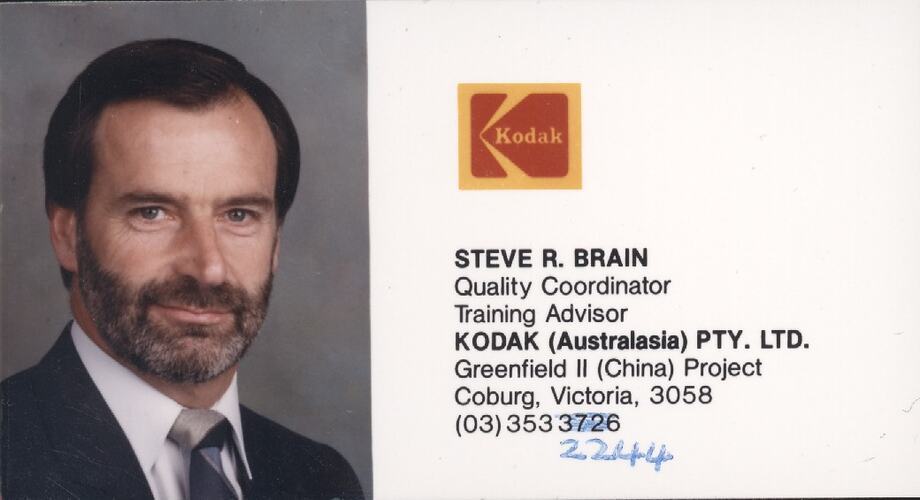

Steve Brain, Kodak Australasia Pty Ltd: Quality Control, with a Year in China, 1958 - 1991

Steve Brain was expected to work in his family's orchard, but decided he preferred city life. After serving six months National Service - compulsory for boys turning 18 in the 1950s - Steve looked for a career with a future. In 1958 he accepted a job at Kodak Australasia as a film tester at the Abbotsford plant.

Testing film and paper at Abbotsford

In the 1950s Kodak Australasia began manufacturing colour film products. The process involved coating film base and paper with light-sensitive emulsion. Testing was an important part of the operation, to ensure the product was within specifications set by Eastman Kodak in the USA, allowing for differences in factors such as exposure conditions and the particular machinery used. Steve's testing work involved the science of sensitometry (the study of light-sensitive materials) to test Kodachrome film made on the J-7 experimental machine. Steve was subsequently asked to help set up the testing laboratory for colour photographic paper manufacture.

'I was very fortunate that I was with two technical people, Merrik Erban and Michael Platt. We started everything from scratch, and we ran our own experiments; we had to. There were no processing kits available, so we had a formula from the US and we hand mixed everything. So I was kind of learning on the go.'

To help him in his work Steve did a part time photographic science course at RMIT, which reinforced much of what he had learned on the job.

Move to Coburg

When Kodak's new Coburg plant opened in 1961, Steve was put in charge of testing the main range of film and paper, working in Building 7 with a staff of about thirty people. Testing samples at all stages of production was crucial, because any defect, for example an air bubble in the coating, could ruin large lengths of film or paper, with huge cost implications. Samples of product that had been in the distribution centre for some time were also re-tested to ensure that it had not deteriorated.

Steve's next move was to quality control in specialist film products such as x-ray and aerographic film. He often worked with marketing people to deal with customer complaints. Sometimes the fault was with the product, but often the problem stemmed from customer handling. He remembers a case where a hospital made new boxes for their x-ray film using chipboard. When the hospital complained that the x-ray film came out grey and with no density, it was found that fumes from the glue in the chipboard were the cause.

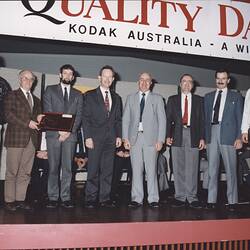

In the 1980s, in the face of increased competition, Kodak embarked on a new 'Total Quality Program' to improve the quality of its products and increase profit margins. Previously the philosophy was to tolerate a certain level of waste from defects in the product, but the new philosophy was to reduce waste to almost nothing by improving production methods and equipment used. Steve remembers 'tightening up the standard on the equipment':

'They might have been using a thermometer and they allowed plus or minus half a degree. And that might have been enough to throw it out. So we then had to use thermometers that were plus or minus 0.1 of a degree. And this was across the whole board. We went to our suppliers of goods, and we helped them to tighten up their specifications, because they might have been selling us a chemical which was 95 percent pure, and we said, "We want 99 percent pure."

Kodak was so successful with the total quality program that it received first prize in the inaugural Australian Quality Award in 1988, under the Australia for Quality Campaign initiated by the Australian Government in 1984.

Establishing a factory in China

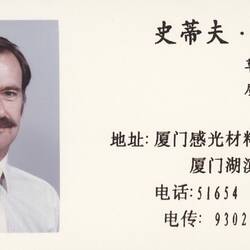

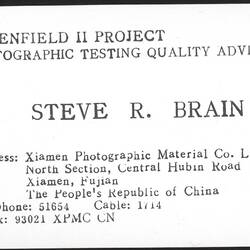

As part of his responsibility for quality control, Steve was involved in establishing a photographic factory in China during the late 1980s. While the project was controlled by Eastman Kodak in America, Steve was one of a small team from Australia - including Arnold Kissack from the Coating Department and Phil Plain from the emulsion department - seconded to train the Chinese staff and commission the new coating machinery.

According to Steve, Australians were chosen for their broad experience, while American staff were highly specialised and would therefore require a larger team of experts for the job. The new Chinese plant was modelled on the Coburg plant, so it was logical for the Chinese workers to be trained on Coburg's machinery.

For six months in 1987 Steve and his colleagues trained a group of fifteen people from China in using the machinery at Coburg. Then Steve, Arnold and Phil, spent the whole of 1988 in Xiamen, China setting up the process for manufacturing colour paper and film, before handing over to the Chinese. As far as Steve was concerned, 'it was really and truly an experience, both culturally and work-wise'. Products from the factory were sold under the brand name Fuda.

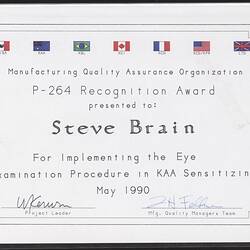

P264 taskforce

When Steve returned to Coburg, quality control was no longer conducted centrally by the Testing Department in Building 7, but was the responsibility of each production area. Steve's new job as Physical Quality Coordinator entailed his participation in P264, an international Kodak taskforce responsible for ensuring that all Kodak products from the various plants around the world were of the same standard.

One of Steve's projects resulted in an innovative standardised method for analysing defects in colour film. However, when he presented it at Eastman Kodak's Head Office in Rochester, USA, the idea was rejected on the belief that it 'couldn't be done'.

In 1991 Steve decided to take early retirement to concentrate on breeding horses. His memories of Kodak are positive. Although he lacked formal qualifications, his career had been fulfilling:

'Mine was all learning by experience, but I was very lucky to be with the right people at the right time.'

References

Beale, Nigel, 'The History of Kodak in Australia', 1983 (unpublished manuscript).

HT 36070 - Kodak News, No. 192, Christmas 1988.

HT 35634 - Interview with Steve Brain, interviewed by Lesley Alves 27 November 2013.

More Information

-

Keywords

Photographic Products, Managers, Manufacturing, Factories, Biographies, Quality Control

-

Authors

-

Article types