Ice was the principle means of refrigeration until the late 19th century. In the United States and Australia non-mechanical refrigerators, known as iceboxes or icechests, were used to keep perishable food fresh. Iceboxes continued to be used as the primary source of refrigeration for many families into the mid 20th century. Figures from the United States show that in 1923 iceboxes outsold mechanical refrigerators but that by 1944 refrigerators were outselling iceboxes by more than two to one. (Iereley 1999, p.246) Figures for Australia are less comprehensive: a survey of appliance purchases in 1923 does not include refrigerators.

By 1955, refrigerators were recorded: 77% of all homes in Brisbane, 83% in Sydney, and 67% in Melbourne owned refrigerators. By 1964, it was estimated that 94% of all Australian households owned a refrigerator (Dingle 1998, p. 124). These figures are supported by recorded oral histories, which demonstrate that in Australia many families were still using iceboxes in the late 1940s and 1950s. (Coleman; The-real-keneth-williams-story; Narrative 708)

Iceboxes

An article in the New York Mirror from 1838 provides a clear definition of the standard icebox: it 'is a double box, the outside of mahogany or other wood, and the inside of sheet-zinc [or tin], the space between being three or four inches. By filling this space with finely powdered charcoal, well packed together, the box is rendered almost heat-proof, so that a lump of ice weighing five or six pounds may be kept twenty-four to thirty-six hours, even more, if the box is not opened too often, so as to admit the hot air from without. Of course while it is closed the air contained within it, being in contact with the ice, is reduced to nearly the same temperature; and meat is preserved perfectly sweet and good, the same as in winter. The interior of the refrigerator is provided with shelves for the reception of dishes, bottles, pitchers, etc.; and thus, by very simple contrivance, joints of meat are kept good for several days, wine is cooled, butter hardened, milk saved from 'turning', and a supply of ice kept on hand for the more direct use of the table.' (Quote in Ierley 1999, p. 168) The means of insulation described above was not standardised; fur pelt, hair, cork, wool, felt, ash and later asbestos were all used as insulating materials. The placement of the ice was also not standardised, though by the end of the nineteenth century it was generally placed in a tray at the top of the unit. A pipe for melted water ran from the ice tray to a drip tray underneath the icebox. This configuration allowed for air to circulate, enhancing the cooling effect - 'the denser cool air descending to the bottom and displacing the lighter warmer air, which rose to the top.' (Ierley 1999, p. 169)

Refrigerators

Domestic refrigeration was a by-product of the desire to create ice commercially and a growing interest in shipping fresh produce overseas. 'Climate and distance forced Australians to be innovative in refrigeration.' (AATSE 1988, p. 95) Though other countries had successfully lowered temperatures mechanically by the mid 19th century, it was Australians who developed the mechanical means to manufacture ice, the precursor to modern refrigeration. In Geelong in 1851, James Harrison, using an ether compression machine, succeeded in his quest to manufacture ice on a commercial scale. He patented his process and apparatus in 1856; however the venture was not a commercial success. Eugene Dominique Nicolle was another inventor based in Australia who experimented with mechanical refrigeration. In 1861 and 1863 he took out patents for an ice making machine that relied on the ammonia absorption process. In 1867 Nicolle 'advertised a domestic refrigerator which was an icebox of improved design and in the seventies . he marketed a small household refrigerator based on the principle of the heat of solution of solutes.' (Farrer 1980, p. 197) Patents for air expansion machines were also taken out by B.G. Sloper in 1858 and J. Davey Postle in the late 1860s. American designs eventually came to dominate the refrigeration market.

A shortage of natural ice in 1890 provided an impetus to experiment with mechanical means of making ice which ultimately resulted in the creation of domestic refrigerators. The first domestic refrigerator sold in America was a manually operated machine produced by Mr J.M. Larsen in 1913. In 1918 the first automatic, mechanical refrigerators were sold; sixty seven of these refrigerators, made by Kelvinator and engineered by E.J. Copeland, were sold in this year. In 1926, the General Electric Monitor Top came onto the market 'after eleven years of experimenting'. (Althouse 1952, p. 2) By 1940 the North American market was dominated by four manufacturers: General Electric, Westinghouse, Kelvinator, and Frigidaire. (Cowan 1983, p. 139)

In Britain the first refrigerator was sold in 1921; it was a French compressor design. Frigidaire was manufacturing in Britain by 1923. In Australia, the first domestically designed and manufactured refrigerators were made by Sir Edward Hallstrom. In the 1920s they used kerosene as their power source, but in 1935 Hallstrom introduced the 'Silent Night' which ran on electricity or gas. The Silent Night was cheap to buy but incredibly expensive to run. As recorded in one oral history, 'operating costs were so astronomical that Sir Edward came to an arrangement with the Electricity supply people. He subsidised the electricity accounts of people buying and operating his refrigerator.' (the-real-kenneth-williams-story)

Other Australian manufacturers gradually entered the refrigerator market including A.G. Healing in the late 1930s; Charles Hope, Colda, and Kirby (an Australian company with licensing agreements with two American refrigeration companies, Crosley and Tecumseh) in the mid 1940s. Some American manufacturers established plants in Australia to manufacture domestically: for example General Motors (in 1926), Kelvinator and Westinghouse.

In 1920, a domestic refrigerator in America cost on average $600. At the height of the depression, 1929, refrigerators cost on average $292, and by 1940 were as little as $154. The fall in prices reflected an increase in production levels: 10,000 units in 1920; 840,000 in 1929; and 2,720,000 in 1940. (ASRE 1943, p. 341) This level of production met export as well as domestic markets; in 1936-37 the USA exported around 200,000 domestic refrigerators. The growth in refrigerator manufacturing and consumer demand was the result of aggressive marketing campaigns. In 1923 the industry spent $45,000 on advertising; in 1931 it spent $20 million. The advertising message was one that assumed purchase; it did not dwell on the superiority of refrigerators over iceboxes, rather it explained how families could afford refrigerators, which model suited their needs best, and how to use it once purchased. Thus household ownership of refrigerators in the United States went from 10% in 1930 to 56% in 1940. By 1960 the percentage was up to 80 in the USA; in Australia it was up to 90%. (Strasser 1982: 265-267; Cowan 1983: 196)

Early mechanical refrigerators used ammonia, methyl chloride or sulphur dioxide as refrigerants, all highly toxic gases. A series of fatal accidents in both the home and work place in the 1920s - from leaking refrigerants - encouraged researchers at General Motors and Du Pont to explore alternative refrigerants. Thomas Midgely, an engineer at General Motor's Frigidaire division, developed the gas Chlorofluorocarbon (CFC) in the late 1920s. CFCs were extremely stable, chemically inert, non-toxic, and non-flammable. Produced by DuPont under the brand name Freon, they were the miracle chemical of their time and were used by all refrigerator manufacturers until the early 1980s when the devastating effect they had upon the Ozone layer was brought to public attention. A suitable non toxic, environmentally friendly, replacement to CFCs is still being researched. In the interim, hydrofluorocarbons are used as refrigerants.

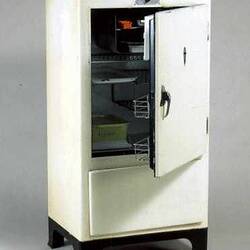

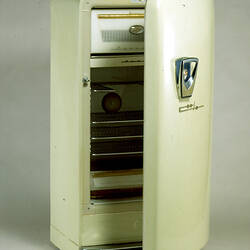

By the 1930s, refrigerator design focused upon aesthetic and functionality. Users by now assumed that the refrigerator would operate satisfactorily. Issues that became important to the consumer were 'increased food storage volume, reduced energy consumption, greater cooling capacity, lower cost, lower noise level and improved appearance.' (ASRE 1943, p. 341) Early refrigerators resembled iceboxes, with wooden bodies and simple interiors. By the 1930s refrigerators were constructed of enamelled metal and reflected contemporary stylistic trends. Interiors were designed with convenience and use in mind. In 1933 Crosley patented the first door shelves; by the early 1940s most refrigerators had freezer compartments with mechanical release ice trays, butter compartments which maintained a slightly higher temperature to keep butter spreadable, rustproof shelving, left or right hand opening doors, utility shelves for bottles, meat trays and vegetable drawers. (Ierely 1999, p. 246)

The development of affordable, mass produced whitegoods was to impact upon the design of household kitchens. In the post World War II period, 'the major components of the kitchen - the range, the refrigerator and the sink . - were .designed to be placed one next to the other.' (Ierley 1999, p. 247) In 1945, this concept was developed further as manufacturers set standard dimensions for kitchen units and appliances. The development of new materials (eg. Laminex and Formica) and paint colours were also employed in kitchen design, so that by the mid 20th century refrigerators came in a variety of fashionable colours; the Frigidaire range by General Motors lead this trend.

References:

2004. 'Environmental Damage from CFCs'. Available online at www.es.flinders.edu.au/~mattom/science+society/lectures/illustrations/lecture35/cfc.html (22nd December 2004).

Althouse, Andrew & Turnquist, Carl H. (1952), Modern Electric and Gas Refrigeration. (5th edition), The Goodheart-Willcox Co., Chicago

American Society of Refrigerating Engineers (ASRE). 1943. Refrigerating data book. (5th edition). New York: The American Society of Refrigerating Engineers.

Australian Academy of Technological Science and Engineering (AATSE). (1988). Technology in Australia 1788-1988. Melbourne: Australian Academy of Technological Science and Engineering.

Coleman, Ruth. Memories of Childhood. Available online at suthshirehistsoc.netfirms.com/memories%20of%20childhood.htm (3rd January 2005).

Cooper, Madison. (1905). Practical Cold Storage, Chicago, Nickerson & Collins Co.

Crawhall, T.C. & Lentaigne, B. (1934). Guide to the Refrigeration Exhibition. And a brief account of the historical development of mechanical refrigeration. Science Museum April-August 1934. HMSO, London

Cuffley, Peter. (1993). Australian Houses of the Forties & Fifties. The Five Mile Press, Victoria

Dingle, Tony. (1998). 'Electrifying the Kitchen in Interwar Victoria', Journal of Australian Studies, no. 57, pp. 119-127

Farrer, Keith T.H. (1980). A Settlement Amply Supplied. Food technology in Nineteenth century Australia, Melbourne University Press, Victoria

Ierley, Merritt. (1999). The Comforts of Home. The American house and the evolution of modern convenience. New York: Clarkson Potter Publishers.

Lane, Terry. (2002). The National Interest: Ozone, Solar Research, Commercialisation. Available online at www.abc.net.au/talks/natint/stories/s6822544.htm, 22/09/2002.(22 Dec 2004)

McNeil, Ian (ed). (1990). An Encyclopaedia of the History of Technology, Routledge, London

O'Callaghan, Judith (ed). (1993). The Australian Dream: Design in the Fifties. Powerhouse Publishing, Sydney

Cowan, Ruth Schwartz. (1983). More Work For Mother: the ironies of household technology from the open hearth to the microwave. Basic Books, Inc., New York

Strasser, Susan. (1982). Never Done: a history of American housework, Pantheon Books, New York

The-Real-Kenneth-Williams-Story. A Coin Operated Gas Meter, More Music and a Witch. Available online at pages.zdnet.com/hookares/the-real-kenneth-williams-story/id2

More Information

-

Keywords

-

Authors

-

Article types