Summary

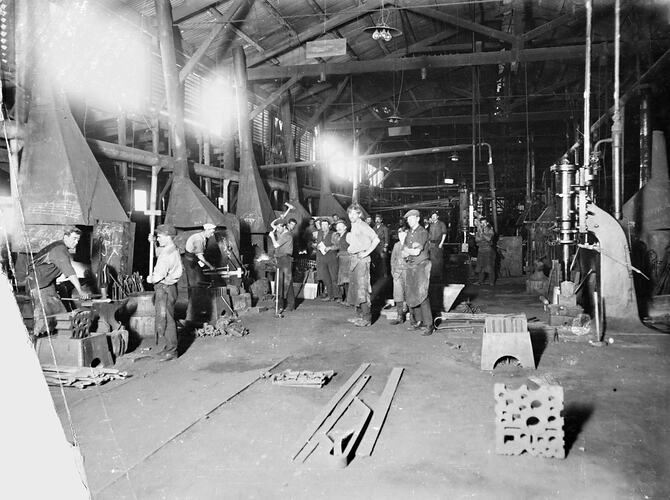

Description of Blacksmiths Shop which operated at Sunshine Harvester Works.

Year established: 1904

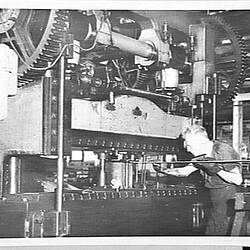

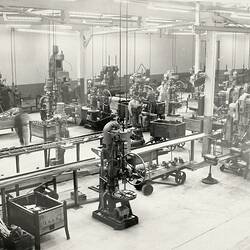

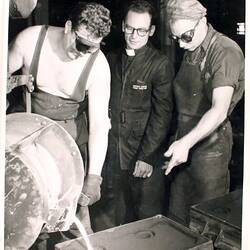

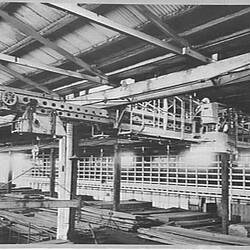

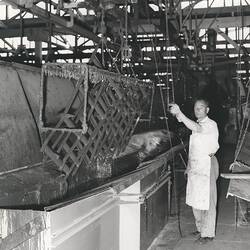

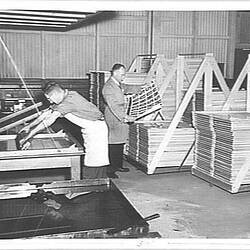

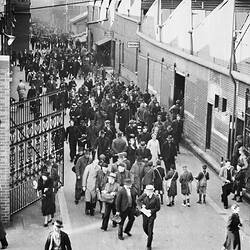

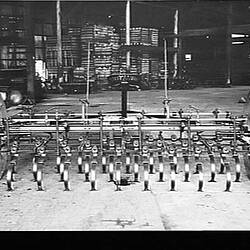

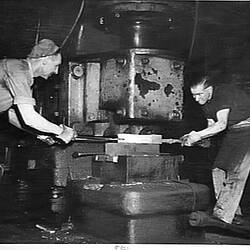

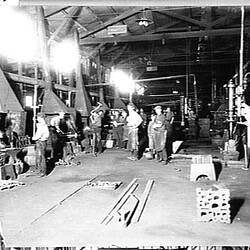

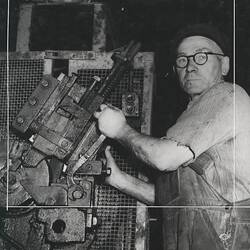

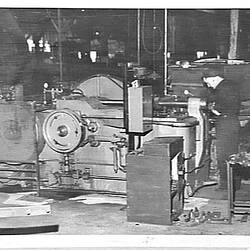

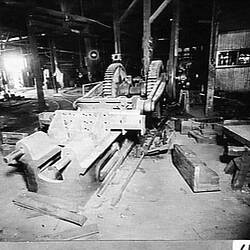

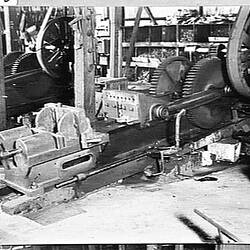

The Blacksmiths' Shop was one of the Sunshine Harvester Works' oldest departments. It produced forged parts for various items including cultivator tynes, plough shares and beams, tyne-points, links and formed bars. The factory's front gate (located at Russell Street) were manufactured in this department by Charlie Pippett in 1922.

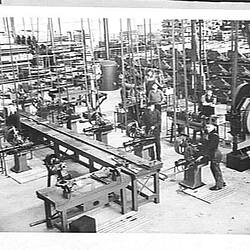

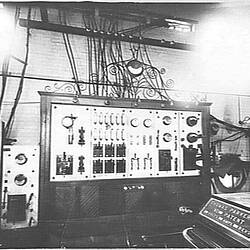

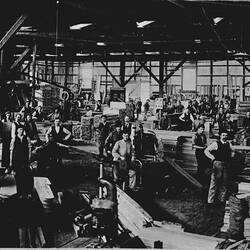

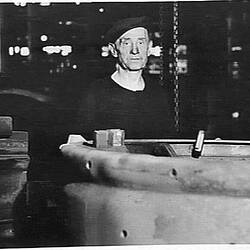

At its peak, there were 76 workers in the shop. During World War II, the department produced an estimated 7,000 metal grids per day. Conditions in the shop were extreme as workers endured intense noise, severe heat, dirt, fumes and smoke emanating from furnaces and machinery. Space in the area was cramped due to the number of machines. Blacksmithing was physically demanding. The company supplied employees with salt tablets to deal with bodily cramping.

Merv Brooks arrived at the Blacksmiths' Shop in 1941 after training as a blacksmith in the Riverina district. He recalls the intensity of working in the area:

McKay's had a big furnace working on a blower, run on oil and air. It gets real white hot. All day we were looking in there pulling bars of iron out, taking them over to the presses and forging them . We worked on that all day and the heat was about 125° Fahrenheit. If it got to 125°, we got a pennyhap'ny an hour more. My first week's wages when I came down here was ten pound and seven pence and I thought I was made . I did all the welding on the anvil. I used to love the anvil because I served my time (apprenticeship) on the anvil.

. We used to make 700 or 800 cultivator points for harvesters each day, out of about eight or nine presses. We used to do different sizes and different types in a day, and we'd be on that press all day, feeding them in. Out of the fire they'd bring a stack of six or seven at a time. We'd keep our presses going all day, kicking one out and putting another one in, kicking one out, putting another one in - just stopped there all day or 12 hours in front of the fire doing those . All the drop hammers, they went by the board, only a matter of about seven or eight years ago. They used to have one driven on air pressure that was a ton weight in the head. I saw a bloke lose his hand in it one day . If the pin wasn't in properly so as to keep the air and hammer up, well, it fell. One bloke couldn't have put the pin in properly and this young bloke lost his hand under it. (Faulkner, Duty Nobly Done, n.p)

... The work clothes were taken off at night and would stand up by themselves ready for you to step into the next day, stiff with perspiration (personal recollections, held at Museum Victoria).

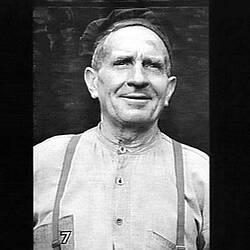

Other known workers in the Blacksmiths' Shop included Charlie Day.

- References

- Sunshine Review 1950, 'A Craftsman's Monument', No. 9, p.3.

- Merv Brooks and Ray Browne (former Sunshine Harvester Works employees), personal recollections held at Musuem Victoria, June, July and October 2000; October 2002.

- Faulkner, R (ed) 1986, Duty Nobly Done: Sunshine Harvester Diary, 1987. Melbourne's Living History Museum of the West, Footscray.

- Sunshine Harvester Works, Factory Plan, 1904. Held at Museum Victoria's H.V McKay Sunshine Collection, registration no. HT 9474.

More Information

-

Keywords

-

Authors

-

Article types