Summary

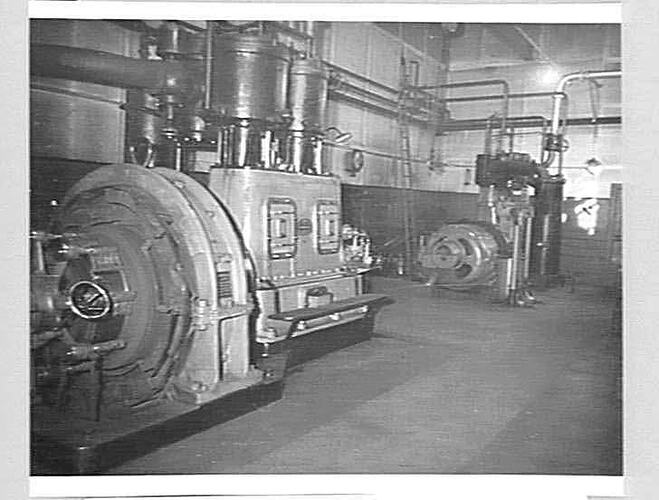

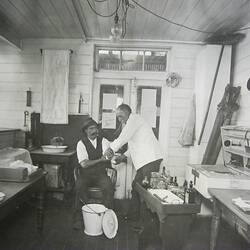

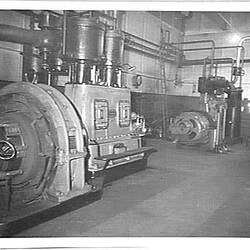

Description of the Sunshine Harvester Works' Compressor Room

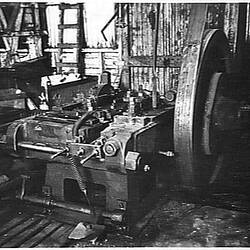

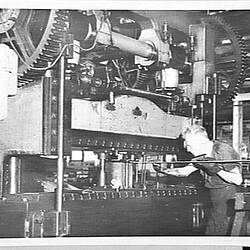

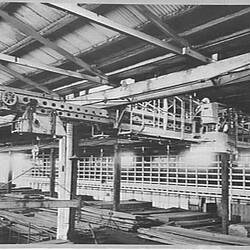

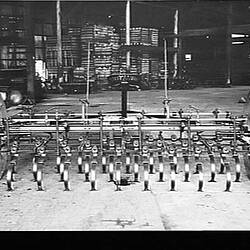

The Compressor Room serviced all air-operated equipment throughout the Sunshine Harvester Works factory, such as air hoists, air cylinders, air chucks and air clutches. The Compressor Room was controlled by personnel from the Electricians Department. Compressors were maintained in immaculately clean condition, with all copper and brass fittings polished to marine standards. Of the three large compressors, one was usually kept in reserve to enable on-going maintenance or to cover a break-down.

The compressors maintained a constant pressure of approximately 90 lbs per square inch. The compressors were started several hours prior to the factory's opening, so that the air-lines were at operational pressures. Sometimes the compressors were required to run 24 hours a day to cover shift work.

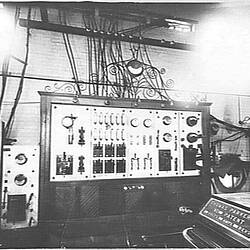

As well as three large compressors, equipment in the room included a combination electrical and instrument board and a work bench. A large compressed air storage vessel was located outside the room. It was approximately six feet in diameter and 20 feet long. The cooling medium for the compressors was water-pumped from the cooling dam adjacent to the Brass Foundry. At least one employee was required to be on duty at all times when compressors were in operation.

- References

- Ray Browne and Ken Porter (former Sunshine Harvester Works employees), personal recollections held at Museum Victoria, October 2001 and June 2006.

More Information

-

Keywords

-

Authors

Ms Snjez Cosic, Mr Ken Porter, Mr Raymond (Ray) Cyril Browne

-

Article types