Summary

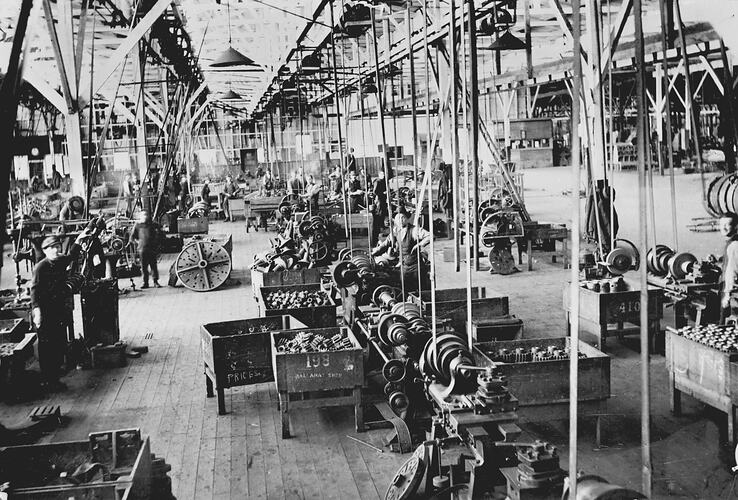

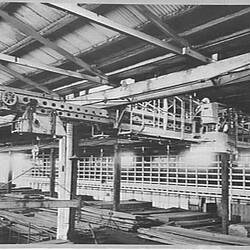

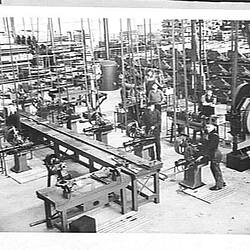

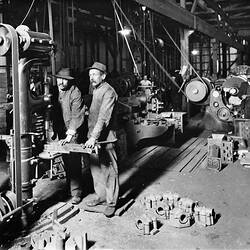

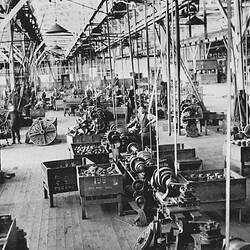

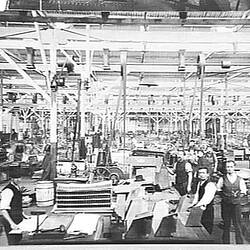

Overview of belt-driven machinery at Sunshine Harvester Works.

Year established: circa 1913-1918.

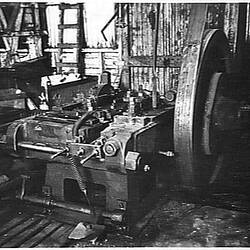

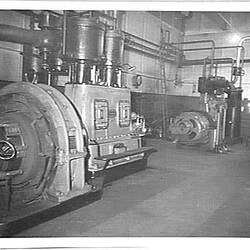

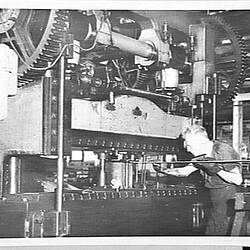

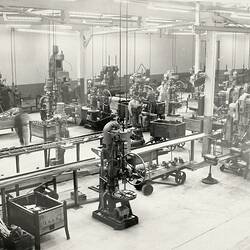

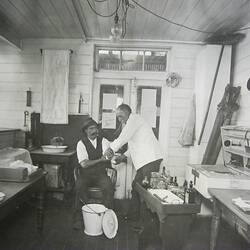

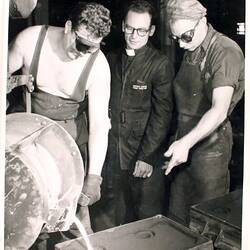

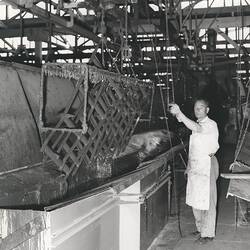

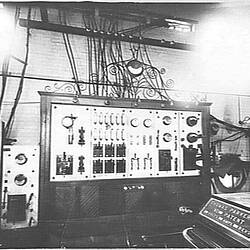

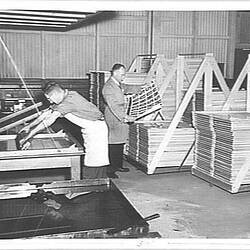

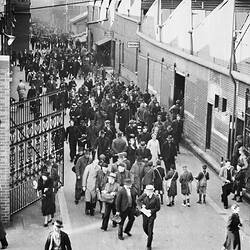

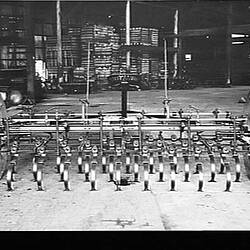

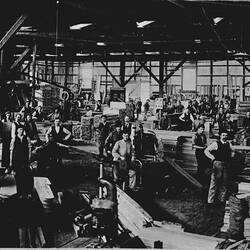

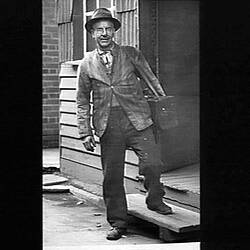

Until the mid-1950s, most machinery in the Sunshine Harvester Works was driven by flat belts from overhead shafting and pulleys. To maintain continuous production, a 'beltman' repaired and replaced the huge range of belts throughout the plant.During the 1930s and 1940s, Sam Mitchell worked as a 'beltman'. Charlie Stonehouse took over when Sam retired. Flat belts were made of leather and were used in conjunction with the overhead shafting system. The belts moved at a rapid rate. They posed a safety threat to nearby workers who could easily get caught in the belts by their hair or clothing.

After World War II individual electric motors were fitted to each factory machine. V-belts were used and eventually all overhead shafting was removed. This also complied with government safety regulations.

The beltman's 'shed' was originally located adjacent to the power house on Burma Road. It later became part of the Maintenance Department, adjacent to the No. 11 Tool Toom.

- References

- Sunshine Review 1948, 'Sunshine Personalities', Vol. 5, No. 2, pp.8.

- H.V McKay, Factory Plan, 1918. Held in Museum Victoria's H.V McKay Sunshine Collection, registration no. HT 9482.

- Ray Browne and George Hales (former Sunshine Harvester Works employees), personal recollections held at Museum Victoria, July 2000 and October 2006.

More Information

-

Keywords

-

Authors

-

Article types